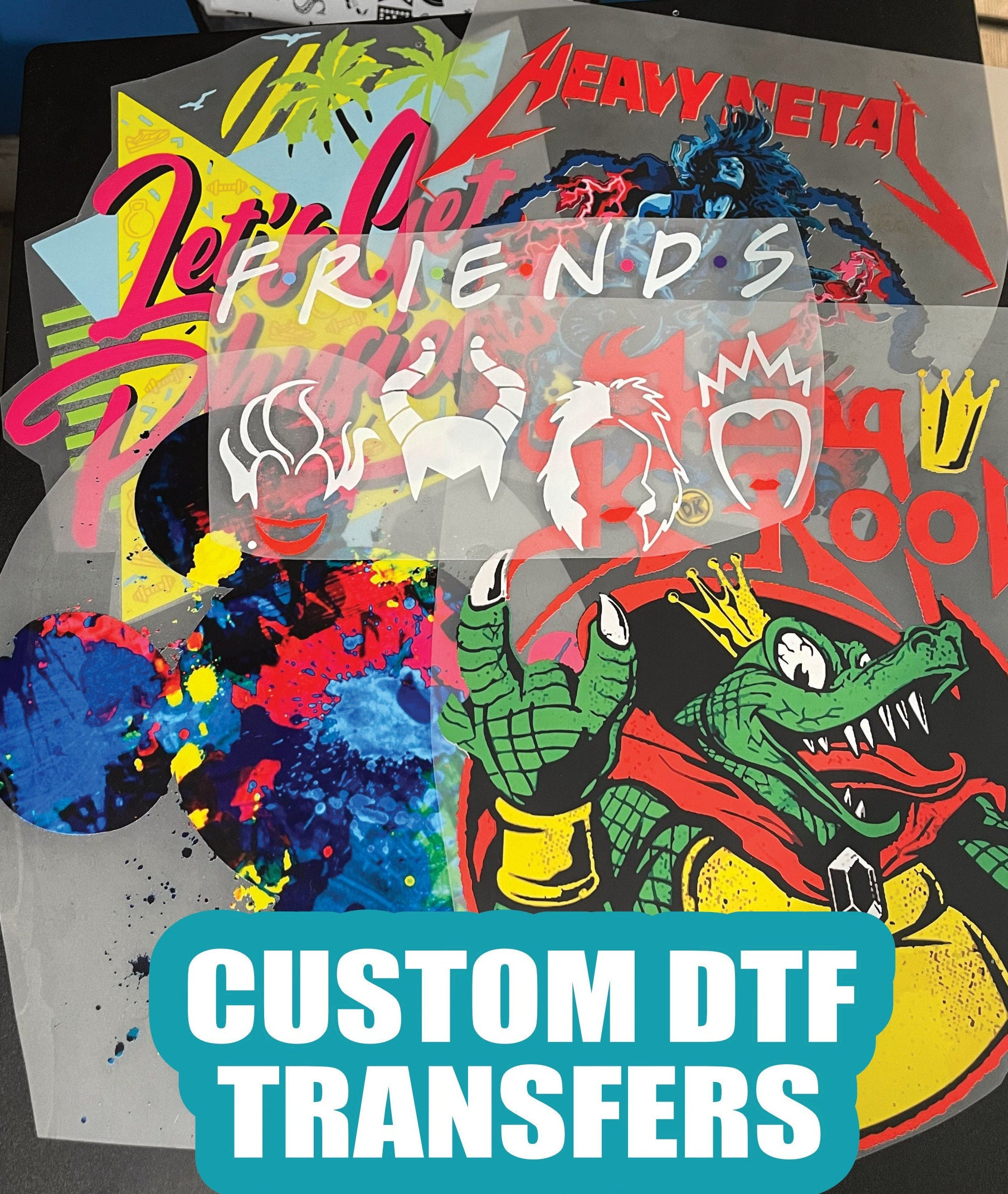

Direct-to-Film (DTF) transfers have emerged as a groundbreaking innovation in printing technology, capturing the attention of both businesses and creatives alike. With their ability to produce vibrant, high-quality designs on a variety of substrates, DTF transfers are quickly becoming the go-to choice for custom transfer printing services. This innovative DTF printing technology not only delivers excellent results but also supports sustainability in print production by minimizing waste and environmental impact. Whether you’re crafting unique apparel or promotional items, the flexibility and ease of use associated with DTF transfer applications allow for endless creative possibilities. Dive into the world of DTF transfers and discover why they are revolutionizing the art of printing and design.

Also referred to as Direct-to-Film transfers, this advanced method of printing has reshaped the landscape for artists and entrepreneurs seeking high-quality imagery on fabric and other materials. Utilizing state-of-the-art printing techniques, DTF transfers allow for detailed and colorful outputs that surpass traditional methods. The process is not only efficient but also aligns with eco-friendly practices, appealing to environmentally conscious creators. As the demand for personalized products grows, DTF technology emerges as a trusted solution for custom designs, making it an ideal choice for various applications in the creative industry. Embracing this cutting-edge approach opens new doors for innovation and sustainable practices in the market.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology offers a seamless transition for anyone looking to create high-quality designs with vibrant colors. This innovative method involves printing on a special film, which is then transferred to various materials using heat and pressure. Unlike traditional printing techniques, DTF allows for greater detailing, ensuring that intricate designs come out just as envisioned. With the advent of DTF technology, businesses can manage a wide range of colors and gradients, making it a superior choice for custom apparel and merchandise.

Furthermore, the DTF printing process provides crafters with the flexibility to experiment without the risks associated with traditional methods. This liberating approach encourages creativity and innovation, leading to truly unique piece creation. The ability to print intricate designs ensures that the finished products meet the increasingly high standards of modern consumers.

The Benefits of Using DTF Transfers

One significant advantage of using DTF transfers is the unmatched print quality they provide. DTF transfers produce sharp, crisp designs that rival traditional screen printing results, allowing for vibrant visuals that truly stand out. This technology enables users to create custom designs with subtle gradients and complex patterns, suiting the needs of businesses and craft enthusiasts alike. High-quality DTF transfers also boast impressive durability, resisting fading and peeling over time, which is crucial for creating long-lasting products.

In addition to quality, DTF transfers offer environmental benefits through sustainability practices. By minimizing waste and utilizing efficient printing processes, more conscious brands can align their values with sustainability goals. This eco-friendly aspect is increasingly attractive to consumers, enhancing brand loyalty and customer satisfaction.

How to Choose the Best DTF Transfers for Your Projects

When sourcing the best DTF transfers, the importance of thorough research cannot be overstated. Begin by exploring various suppliers and comparing reviews to find the most reputable sources. Testimonials from other users can provide valuable insights into the quality of the transfers offered. Websites dedicated to printing resources can guide you in identifying suppliers with a track record of producing high-quality DTF transfers that meet your project needs.

It’s also essential to prioritize quality over price. Opting for affordable transfers might save money initially but can lead to higher costs in the long run due to the likelihood of needing replacements due to quality issues. Understanding your project requirements, such as the desired design intricacy or material compatibility, will further refine your selection process and ensure you choose the best DTF transfers for your specific needs.

Embracing Custom Transfer Printing Services

The rise of personalized designs has led to a significant increase in interest towards custom transfer printing services, particularly in DTF technology. These services empower crafters and businesses to unleash their creativity by transforming unique ideas into tangible products. Users can create one-of-a-kind designs reflective of their brand identity, fostering a deeper connection with their audience.

Choosing a service like DTFPrinter offers a streamlined approach to producing custom transfers, making it accessible even for those new to the world of printing. As a result, brands can enhance customer satisfaction by providing personalized solutions that address specific preferences, ultimately leading to higher levels of loyalty and repeat business.

Best Practices for Applying DTF Transfers

Achieving professional-quality results with DTF transfers relies heavily on following application guidelines set by the manufacturers. Every transfer may have unique temperature and pressure settings that ensure durability and vibrant colors upon application. Developing a consistent application routine will help maximize the transfer quality while minimizing the need for corrections.

Testing new designs or materials before full-scale application is another critical best practice. A trial run can help identify potential issues, allowing you to make adjustments as needed. By testing smaller pieces first, you save resources and ensure confidence in the final product before committing to larger orders.

Maintaining Your DTF Printing Equipment for Success

Proper maintenance of your DTF printer and heat press can significantly impact the quality of your prints. Regularly servicing your equipment ensures optimal performance and longevity, reducing the risk of technical issues that could lead to inconsistent print results. Schedule routine checks to clean components and verify that everything is functioning as intended.

Additionally, keeping up with software updates and calibration will help maintain the quality of your DTF printing output. By investing time in equipment maintenance, you can continue to produce high-quality DTF transfers that exceed your business and personal project expectations.

Frequently Asked Questions

What are the benefits of using the best DTF transfers for custom apparel?

The best DTF transfers offer high-quality, vibrant prints comparable to traditional screen printing. They provide excellent durability and allow for intricate designs, making them ideal for custom apparel. Additionally, DTF transfers are flexible, allowing crafters to experiment with various designs without the commitment required in other printing methods.

How does DTF printing technology support sustainability in the printing industry?

DTF printing technology supports sustainability by significantly reducing waste compared to traditional methods. This technology utilizes efficient inks and transfer processes that minimize material waste, aligning with eco-conscious brands’ sustainability goals and enhancing their positive brand image.

What should I consider when sourcing custom transfer printing services for DTF Transfers?

When sourcing custom transfer printing services for DTF transfers, prioritize quality over price. Research various suppliers by reading reviews and examining product samples. Additionally, understand your specific project needs, such as durability requirements for clothing or accessories, to ensure you select the best option.

What applications are best suited for DTF transfer printing?

DTF transfer printing is versatile and well-suited for various applications, including custom apparel, merchandise, and DIY crafts. It is particularly effective for intricate designs and vibrant colors on textiles, accessories, and promotional items, making it a popular choice among crafters and businesses alike.

How can I ensure that my DTF transfers are applied correctly for the best results?

To ensure optimal results when applying DTF transfers, always follow the manufacturer’s application guidelines regarding temperature and pressure settings. Conduct test runs with new designs or substrates to refine the process and maintain your DTF printer and heat press in good condition to prevent printing inconsistencies.

What types of designs can I create with DTF printing technology?

DTF printing technology allows for a wide range of designs, from simple graphics to intricate patterns with gradients and unlimited colors. This flexibility caters to personalized branding or creative projects, enabling users to express their unique style and enhance customer satisfaction with tailor-made designs.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | DTF transfers print designs on a special film using high-quality inks, which are then transferred to substrates with heat and pressure, allowing for vibrant colors and intricate designs. |

| Why Choose DTF Transfers? | 1. High-Quality Results: Produces sharp, vivid prints. 2. Sustainability: Reduces waste and aligns with eco-friendly practices. 3. Flexibility: Allows experimentation with designs. |

| How to Source DTF Transfers | Research various suppliers, prioritize quality over price, and understand your project’s needs to find the best DTF transfers. |

| Custom Transfer Printing Services | Custom DTF transfers allow unique branding and designs, enhancing customer satisfaction and accessibility for all skill levels. |

| Tips for Using DTF Transfers | 1. Follow manufacturer application guidelines. 2. Test designs before full application. 3. Maintain equipment for optimal results. |

Summary

DTF Transfers have emerged as a groundbreaking solution in the printing landscape, combining quality with sustainability. By enabling crafters and businesses to achieve intricate and vibrant designs with minimal waste, DTF Transfers represent a significant advancement in custom printing technology. Embracing DTF transfers not only allows for creativity but also supports eco-friendly practices, appealing to a wide range of consumers. With the right approach to sourcing and application, DTF Transfers can elevate your printing projects, foster customer loyalty, and align with modern sustainability goals.