DTF Gangsheet is at the forefront of innovative printing technology, specifically designed for custom apparel enthusiasts and small businesses. This method of Direct to Film (DTF) printing not only allows for vivid color reproduction but also harnesses the power of gang sheet printing to maximize efficiency and reduce waste. By combining multiple designs into a single sheet, DTF gang sheets streamline the printing process, enabling you to create stunning apparel without sacrificing quality. In this article, we delve into the intricacies of DTF printing, exploring the techniques and tools you need to master the art of gang sheets for effective heat transfer printing. With our comprehensive DTF printing guide, you’ll be well-equipped to elevate your custom apparel designs to new heights of creativity and professionalism.

When it comes to creating unique clothing designs, mastering the art of film printing is essential. Utilizing a gang sheet, which consolidates several graphic designs onto one printed medium, can significantly enhance your production capabilities. This approach not only saves materials and time but also allows for a more streamlined method of transferring images onto various fabrics through heat application. By leveraging the principles of heat transfer printing within the framework of custom garment decoration, you can unlock an impressive range of artistic possibilities. In this guide, we will navigate through the essential strategies and best practices associated with DTF printing and gang sheet design.

The Basics of DTF Printing

DTF printing, or Direct to Film printing, is a modern method that allows for the transfer of intricate designs onto various textiles. It utilizes a specialized film coated with a layer of adhesive, providing vibrant colors that stand out. This printing technique is favored for its versatility and efficiency, making it a popular choice among small businesses and custom apparel makers. One of the key advantages of DTF printing is its ability to handle complex designs without the limitations typically seen in traditional screen printing.

Understanding the fundamentals of DTF printing involves recognizing its applications and benefits. This method can be used on various fabrics including cotton, polyester, and blends, enabling businesses to cater to a wide range of customer preferences. The technology allows for rapid production times, encouraging personalization and customization. As you explore this process, it’s important to familiarize yourself with the different materials used, as they can affect the final print quality and durability.

Understanding the Importance of Gang Sheets

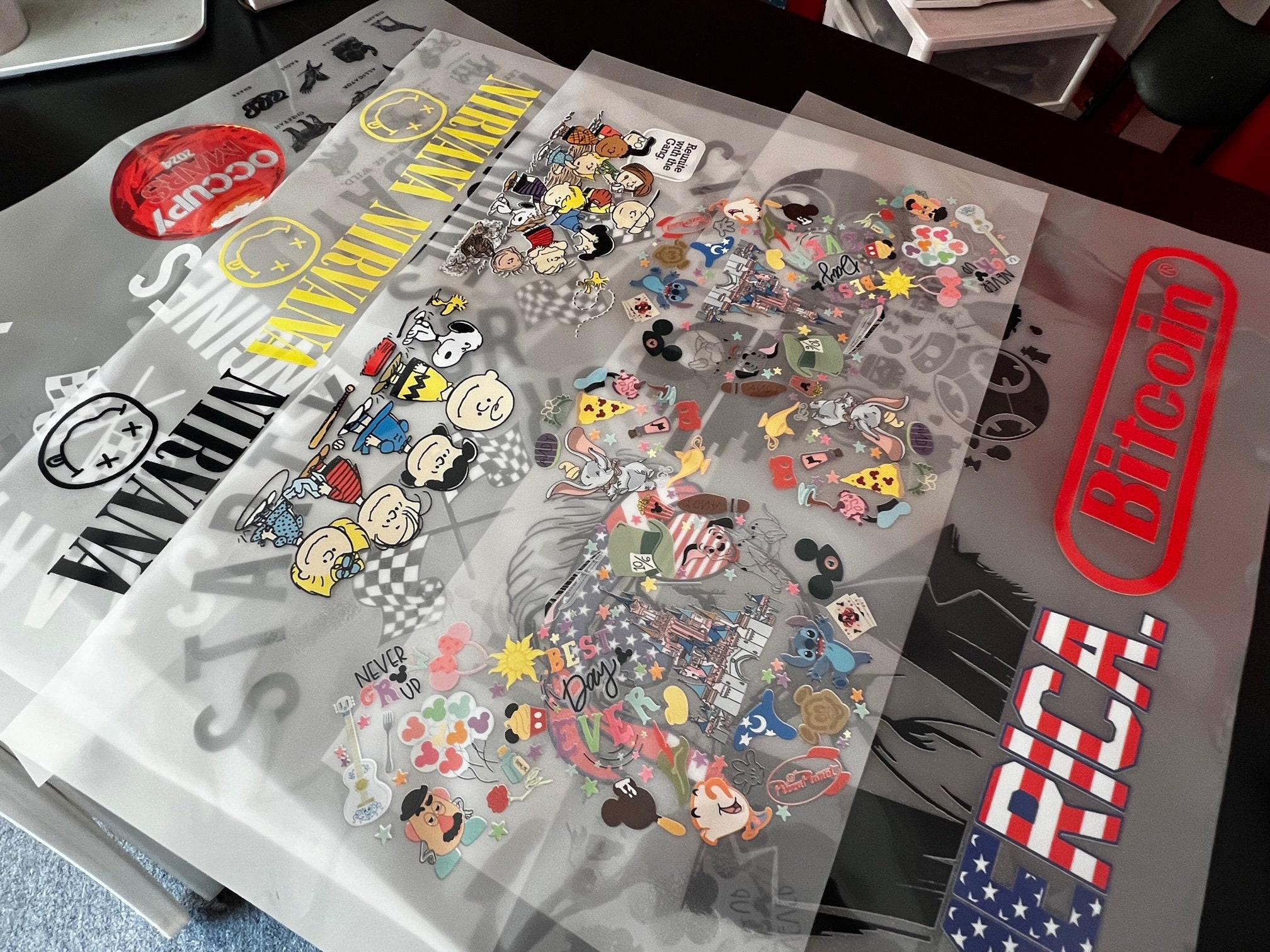

Gang sheets play a pivotal role in enhancing the efficiency of the DTF printing process. By combining multiple images or designs into a single layout, gang sheets maximize the use of the film, allowing for cost-effective printing. This practice not only conserves materials but also reduces setup times significantly, enabling businesses to operate more efficiently. As a result, companies can fulfill orders faster, which is crucial in a competitive market where quick turnaround times can lead to increased customer satisfaction.

In addition to efficiency, gang sheets also contribute to sustainability in the printing industry. By minimizing waste and optimizing resources, custom apparel shops can operate with a greener mindset. When designing gang sheets, careful planning and consideration of layout ensures that excess material is not discarded. This eco-friendly approach not only caters to environmentally conscious consumers but can also enhance a brand’s reputation.

How to Choose the Right Software for DTF Gangsheet Design

Selecting the appropriate software for designing your DTF gangsheet is crucial in achieving optimal results. Popular options like Adobe Illustrator, CorelDRAW, and Inkscape have robust features that can streamline the design process. These software tools offer capabilities such as vector image handling, which is essential for maintaining the quality of your prints. Additionally, mastering these platforms can greatly enhance your efficiency when creating layouts for multiple designs on a gang sheet.

When choosing software, it’s important to consider user-friendliness alongside feature sets. Intuitive interfaces can help new users navigate more easily, while seasoned designers may appreciate advanced functionalities for precision design. Tutorials and online resources are abundant for these applications, providing valuable learning opportunities that can boost your DTF gangsheet creation processes.

Preparing Your Images for Efficient DTF Printing

Preparation is key to successful DTF printing, particularly when it comes to the images you intend to use on your gang sheet. The first step involves sourcing high-quality, high-resolution images to avoid pixelation during printing. Intricate details are critical in custom apparel, and blurry or low-quality images can spoil the final product. Additionally, ensuring that images are formatted with transparent backgrounds is essential to minimize unwanted borders during the transfer.

Another important aspect of image preparation is sizing. Each design should be adjusted to fit seamlessly on the gang sheet without overlapping. Improper sizing can lead to wasted materials and longer production times. Additionally, group similar designs together to create a cohesive look, which can contribute to an aesthetically pleasing final layout and potentially reduce ink consumption during printing.

Design Layout Best Practices for Gang Sheets

Creating an effective layout for your DTF gangsheet is both an art and a science. Maximizing the sheet’s area, while ensuring proper spacing between designs, is critical to avoiding complications during the cutting and transfer process. Utilize templates where possible, as these can standardize the design approach and lead to consistent quality in final products. Good design practice also includes considering the color groupings of your images, which can optimize ink usage and enhance the overall visual impact of the prints.

When arranging your designs on the gang sheet, think strategically about how each piece interacts visually. Aim for a balanced composition, which not only maximizes space but also appeals to the eye of the consumer. Experimenting with different layouts before finalizing one can help ensure that you produce prints that stand out and capture attention.

Essential Tips for Successful Heat Transfer in DTF Printing

The heat transfer process is the final step in converting your DTF gangsheet into wearable art, and executing it correctly is vital. Proper setup of the heat press, including temperature and pressure settings, must be tailored to the fabric being used. A common setting involves heat application at around 320°F (160°C) for 10-15 seconds. Ensuring that these parameters are accurately adjusted is crucial for achieving durable and vibrant finishes on the fabric.

Another tip involves the application of adhesive powder to the printed film prior to the heat press process. This enables the ink to bond securely with the fabric, creating a lasting print. As you gain experience with heat transfer techniques, it’s essential to continuously assess your results and make adjustments as needed. Each printing session brings new challenges, and a meticulous approach will lead to improved outcomes over time.

Frequently Asked Questions

What is a DTF gangsheet in DTF printing?

A DTF gangsheet is a layout that combines multiple images or designs printed on a single film sheet for DTF printing. This method optimizes production efficiency, saves material costs, and reduces waste by allowing multiple designs to be printed simultaneously.

How do I create a DTF gangsheet for custom apparel?

Creating a DTF gangsheet for custom apparel involves selecting design software, preparing high-quality images, arranging them efficiently on the gang sheet, and adjusting printer settings for optimal heat transfer. Following best practices will ensure high-quality prints.

What are the advantages of using gang sheet printing in DTF printing?

Gang sheet printing in DTF offers several advantages, including cost savings on materials, reduced printing time through simultaneous printing of multiple designs, and a smaller environmental footprint due to minimized waste.

Can I use DTF printing for white and colored fabrics with gang sheets?

Yes, DTF printing is versatile and can be used on various fabric types, including both white and colored fabrics. When using gang sheets, ensure proper color adjustments and heat settings for excellent print quality on all fabric tones.

What is the recommended temperature and time for heat transfer in DTF gangsheet printing?

For heat transfer in DTF gangsheet printing, it is generally recommended to set the heat press to around 320°F (160°C) for about 10-15 seconds. This helps achieve a strong bond between the design and the fabric.

Where can I learn more about DTF printing techniques and gang sheet creation?

You can explore DTF printing techniques and gang sheet creation through online courses, workshops, tutorials on platforms like YouTube, and joining forums dedicated to custom apparel printing. Continuous learning will enhance your skills in DTF printing.

| Section | Key Points |

|---|---|

| Introduction | Overview of DTF printing and its advantages. |

| What is DTF Printing? | DTF printing allows for vibrant designs on fabrics, simplifying personalization for businesses. |

| Importance of Gang Sheets | Gang sheets combine multiple designs on one film, saving materials and increasing efficiency. |

| Step 1: Choosing Software | Select design software (Adobe Illustrator, CorelDRAW, Inkscape) for effective layout. |

| Step 2: Preparing Images | Use high-quality images with transparency, and size them appropriately. |

| Step 3: Designing Layout | Optimize space, use templates, and group colors to enhance aesthetics. |

| Step 4: Prepare for Printing | Adjust printer settings for ink type and ensure adhesive application is correct. |

| Step 5: Heat Transfer | Apply heat press settings correctly for effective design transfer. |

| Best Practices | Run test prints and continuously learn to improve processes. |

Summary

DTF Gangsheet is a powerful tool for those in the custom printing industry, allowing for creative expression while ensuring efficiency. This ultimate guide reveals how to harness the full potential of DTF printing and gang sheets. By understanding each step—from software selection to heat transfer processes—you can streamline your printing operations and create standout designs. The journey of mastering DTF gangsheet building is filled with opportunities for innovation and creativity. Keep abreast of the latest trends and refine your techniques to stand out in a competitive marketplace.