DTF transfers have emerged as a groundbreaking solution in the custom apparel printing landscape, particularly within the realm of t-shirt transfer technology. This innovative method combines high-quality imaging with incredible flexibility, allowing brands to easily adapt to changing consumer demands. DTF printing stands out by enabling vibrant color reproduction and crisp details that traditional methods often struggle to achieve. As businesses increasingly seek to personalize their offerings, understanding the advantages of DTF printing becomes essential. With minimal setup times and the ability to print on a variety of fabrics, DTF transfers are redefining the rules of custom apparel printing.

Often referred to as Direct-to-Film printing, this revolutionary technique is changing the dynamics of how apparel is produced and customized. By employing specialized films that allow intricate designs to transfer seamlessly onto fabrics, custom garment production has shifted towards an on-demand model, significantly reducing wasted resources. This transition not only streamlines the printing process but also caters to the growing trend of personalized attire, meeting the needs of consumers who crave uniqueness. The rise of this t-shirt transfer technology reflects a broader movement within the industry, where businesses are keen to embrace efficient, eco-friendly practices that align with modern shopping behaviors. The versatility and accessibility of this printing method are setting the stage for a new era in apparel design.

Exploring the Basics of DTF Printing

DTF printing, short for Direct-to-Film printing, is a revolutionary technique that has emerged as a game-changer in the t-shirt printing landscape. It operates by transferring designs printed on a special film directly onto fabrics, enabling vibrant colors and intricate details that were difficult to achieve with previous methods. Unlike traditional printing techniques that require extensive setup, DTF printing simplifies the process, allowing for quicker production times and less waste. This shift not only benefits manufacturers but also significantly enhances the experience for consumers looking for high-quality custom apparel.

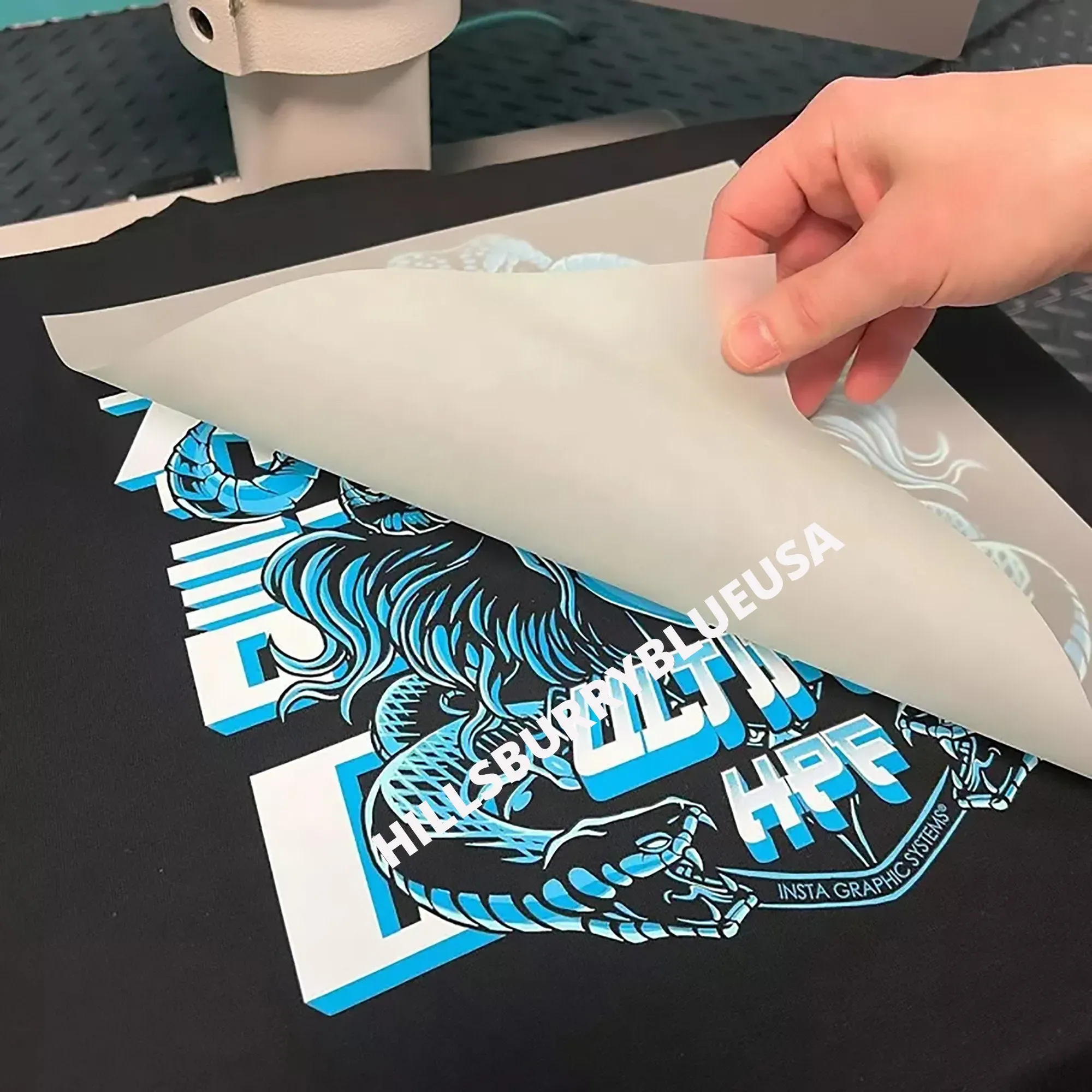

Understanding how DTF printing works reveals its versatility and advantages over other methods. The process begins with printing the design onto a specialized film using high-quality inks. A unique adhesive powder is then applied to the printed design before it goes through a heat press, resulting in a durable transfer that adheres seamlessly to various substrates. This ability to print on different materials, from cotton to polyester, makes DTF printing a preferred choice for custom apparel brands aiming to cater to diverse consumer needs.

The Benefits of Utilizing DTF Transfers

One of the most significant advantages of using DTF transfers is their ability to produce high-quality prints with vibrant colors. DTF technology employs water-based inks that yield bright and long-lasting results, ensuring that designs stand out on garments. This is particularly important for custom apparel brands that prioritize both aesthetics and durability. Customers seeking unique designs will appreciate the color accuracy and detail that DTF printing can achieve, setting their offerings apart in the crowded market of fashion.

Additionally, DTF transfers offer a level of efficiency that traditional printing methods simply cannot match. Businesses can operate on a print-on-demand basis, which means they can fulfill individual orders without the burden of large inventory. This flexibility allows for better resource management and reduces waste, making it a sustainable option for eco-conscious brands. As the demand for customization increases, DTF printing helps businesses stay competitive while meeting the unique preferences of their customers.

DTF Printing vs. Traditional Methods

When comparing DTF printing to traditional methods like screen printing, the differences become apparent. Screen printing often requires extensive preparation time and is typically more suited to large volume orders due to its setup costs. Conversely, DTF printing allows for shorter setup times, making it ideal for small runs and custom designs. This adaptability means that businesses can respond quickly to trends and customer requests without being tied to large production runs.

Moreover, DTF printing is not limited by design complexity. Unlike screen printing, which can become costly with intricate designs, DTF technology effortlessly handles detailed and colorful prints. This feature particularly appeals to brands looking to create intricate graphics or designs that reflect the latest fashion trends. As a result, many businesses are shifting towards adopting DTF transfers to leverage these benefits and keep up with evolving market demands.

Sustainability in DTF Printing Practices

Sustainability has become a key concern for consumers, and DTF printing addresses this issue effectively. Utilizing water-based inks, DTF technology significantly reduces the environmental impact compared to traditional printing methods that often rely on harmful solvents. Brands that incorporate DTF printing into their operations can highlight their commitment to eco-friendly practices, thereby attracting a growing segment of environmentally-conscious customers.

Additionally, the efficiency of DTF printing contributes to sustainability. The print-on-demand nature of this technology minimizes overproduction and waste—key factors in reducing a brand’s overall environmental footprint. By avoiding excess inventory, businesses can operate more sustainably, meeting consumer demands while preserving resources. The combination of quality and eco-friendliness positions DTF printing favorably in the future of custom apparel.

Customization: Meeting Consumer Demands with DTF Transfers

The custom apparel market thrives on personalization, and DTF transfers are perfectly poised to meet this consumer demand. With the ability to create bespoke designs on-demand, brands can offer unique products that resonate with individual preferences. Whether it’s for special events, promotional campaigns, or personal gifts, DTF technology allows for the creation of tailor-made garments that appeal to consumers’ growing desire for uniqueness.

Moreover, the flexibility of DTF transfers means there are no minimum order requirements, making it accessible for small businesses and independent designers. This democratization of printing technology enables even the smallest brands to compete effectively in the marketplace. As a result, DTF printing not only supports individual creativity but also fosters a diverse and thriving ecosystem within the custom apparel industry.

The Future of DTF Transfers in Apparel Printing

As DTF transfer technology continues to evolve, it’s clear that its influence on the apparel industry will only strengthen. The potential for innovation within DTF printing is vast, with possibilities for new materials and printing techniques on the horizon. As brands experiment and adapt this technology, the apparel landscape may witness exciting developments that further push the boundaries of design and customization.

Furthermore, as traditional printing methods strive to maintain relevance in the face of DTF advancements, we may see a shift towards hybrid techniques that incorporate both technologies. This could catalyze a new era in apparel printing—one that leverages the strengths of established methods while embracing the efficiency and capabilities of DTF. As we look ahead, the continued exploration and adoption of DTF technology will undoubtedly shape the future of custom printing.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a special film that can then be transferred onto various fabrics. This innovative process allows for high-quality, vibrant prints on demand, making it ideal for custom apparel printing.

What are the advantages of using DTF Printing for t-shirt transfer technology?

DTF Printing offers several advantages, including quick setup and turnaround times, vibrant color reproduction, and versatility across different fabric types. It allows brands to produce custom designs efficiently while appealing to consumer demands for quality and personalization.

How does DTF printing differ from traditional screen printing methods?

Unlike traditional screen printing, which requires significant setup and is better suited for large batches, DTF printing streamlines the process, enabling on-demand production and customization without the need for bulky equipment or long lead times.

Is DTF Transfers an eco-friendly option for custom apparel printing?

Yes, DTF Transfers utilize water-based inks, which significantly reduce the use of harmful solvents and chemicals. This makes DTF printing a more environmentally friendly option compared to traditional printing methods, appealing to eco-conscious consumers.

What types of fabrics can DTF printing be applied to?

DTF Transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester, and various blends. This adaptability allows businesses to expand their product offerings beyond t-shirts to include hoodies, bags, and more.

How can small businesses benefit from DTF Transfers?

Small businesses can greatly benefit from DTF Transfers as they can produce custom designs without minimum order requirements. This flexibility allows for experimentation with unique designs and helps entrepreneurs cater to niche markets without financial risk.

| Key Points | Details | |

|---|---|---|

| Understanding DTF Transfers | Direct-to-Film (DTF) printing is an innovative technique allowing vibrant, detailed images to be printed on film and transferred onto fabric, enabling high-quality, custom prints on demand. | |

| The Rise of DTF Transfers | With the growth of e-commerce, brands can cater to consumer demands for unique designs and small quantities, exemplified by services like Sam’s DTF Transfers offering no minimum orders. | |

| Advantages of DTF Printing | ||

| Quick Setup and Turnaround | DTF transfers allow businesses to produce custom designs almost instantly, addressing fast-paced market demands. | |

| Vibrant Color Range | DTF printing produces bright, durable colors while keeping the fabric soft, appealing to customers seeking aesthetics and comfort. | |

| Eco-Friendly Practices | DTF uses water-based inks, reducing environmental impact compared to traditional methods. | |

| Versatility Across Fabrics | DTF can print on various materials beyond t-shirts, expanding product lines for businesses. | |

| Customization and Meeting Demands | ||

| Case Study: Sam’s DTF Transfers | By launching premium services and focusing on quality and speed, Sam’s DTF Transfers exemplifies effective adaptation and leadership in the custom apparel market. | |

| Future of DTF Technology | As DTF gains popularity, brands are expected to innovate with new materials and designs, challenging traditional printing methods. | |

Summary

DTF Transfers are revolutionizing the t-shirt printing industry by offering innovative solutions that cater to modern consumer demands for customization and quality. This technology enables businesses of all sizes to produce vibrant, detailed prints with quick turnaround times, making it an indispensable tool in the competitive apparel market. As brands embrace DTF transfers, they not only enhance their product offerings but also align with eco-friendly practices that resonate with conscious consumers. The future is bright for businesses that adapt to this transformative technology, making DTF Transfers a crucial component in the evolution of custom printing.