In the rapidly advancing world of textile printing, **DTF transfers** (Direct to Film) are emerging as a transformative technology, captivating the attention of both manufacturers and consumers alike. This innovative printing method not only offers exceptional quality and vivid color reproduction, but it also aligns with current trends towards sustainability and customization in the fashion industry. As market demand for personalized apparel rises, so too does the significance of DTF transfers, which streamline the production process and reduce costs compared to traditional techniques. By harnessing cutting-edge textile printing technology, businesses are able to meet the growing consumer appetite for unique designs and eco-friendly solutions. This introductory exploration sets the stage for understanding why DTF transfers are not just a trend, but a revolutionary leap forward in how we think about custom apparel and textile printing.

In today’s textile printing landscape, Direct to Film (DTF) printing technology stands at the forefront, offering a fresh perspective on traditional printing methods. Known for its efficiency and quality, this innovative approach enables the creation of bespoke designs that cater to individual preferences in the ever-evolving world of custom apparel. With significant advancements in printing technology, the focus on sustainable practices is also reshaping how companies engage with textile printing trends. The versatility of DTF allows it to be seamlessly integrated across various fabric types, making it a competitive choice in a market that increasingly values ecological responsibility. As brands and designers navigate this new era, the adoption of DTF printing exemplifies a shift towards not only creativity but also towards a more sustainable future in textile production.

The Rise of DTF Transfers in Textile Printing

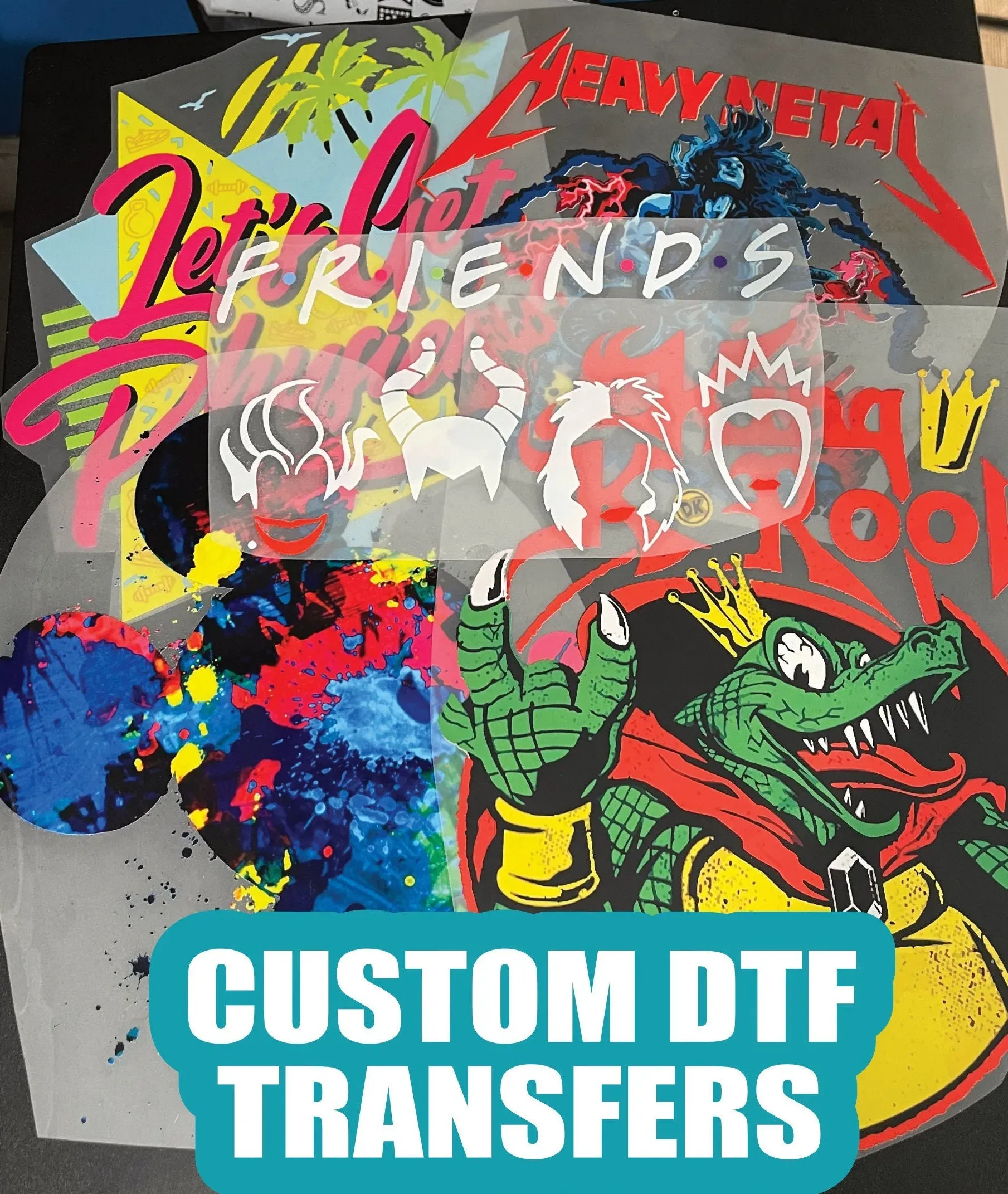

DTF transfers, or Direct to Film printing, have rapidly gained traction in the textile printing sector due to their exceptional adaptability and high-quality output. Unlike traditional printing techniques, DTF transfers allow for intricate designs to be applied efficiently and affordably, meeting the diverse demands of modern consumers. As businesses strive to offer customization, DTF prints stand out by catering to various fabric types, from cotton to blends, enabling an expansive range of applications in custom apparel.

Moreover, the appeal of DTF transfers lies in their ability to maintain vibrancy and durability. The printing technology utilizes advanced ink formulations that bond seamlessly with fabrics, providing longevity that rivals conventional methods. This capability not only satisfies quality expectations but also positions DTF transfers as a viable solution for businesses looking to enhance their offerings in customized textile products.

Trends Influencing DTF Printing Growth

In the realm of textile printing, emerging trends are significantly propelling the growth and popularity of DTF transfers. The rising consumer demand for personalized products is a major catalyst, as shoppers increasingly seek distinctive apparel that reflects their individual styles. DTF printing enables quick turnaround times and the flexibility to create small batch orders, making it an ideal choice for businesses aiming to capitalize on this growing interest.

Additionally, the integration of technology in the printing process is reshaping operational workflows. Businesses that adopt DTF transfers can leverage automated systems to enhance productivity, reduce labor costs, and ultimately offer more competitive pricing to consumers. As these trends evolve, staying ahead of the curve will be crucial for companies looking to thrive in the retail landscape dominated by custom apparel.

The future sights also lean towards the increase in eco-consciousness among consumers and manufacturers alike. DTF printing technology aligns with these sustainability trends as it typically uses less water and generates less waste compared to traditional dye-sublimation methods. The development and use of eco-friendly inks is another factor contributing to a green agenda within textile printing, solidifying DTF transfers as not just a print choice, but an environmentally responsible option.

This shift towards sustainable practices not only appeals to ethical-minded consumers but also allows businesses to market themselves as forward-thinking and environmentally responsible. This aligning of interests between modern consumers and technologically advanced printing processes positions DTF transfers as a frontrunner in the textile industry.

Cost Analysis of DTF Transfers vs. Traditional Methods

When evaluating DTF transfers against traditional textile printing methods like screen printing, it’s essential to consider the cost efficiency that DTF technology offers. DTF printing requires considerably lower initial equipment investments and setup costs, which places this method in a more accessible range for many small and mid-sized businesses. The reduced financial barrier allows emerging brands to engage in the custom apparel market without incurring hefty expenses, creating opportunities for innovation and creativity.

Furthermore, the operational costs associated with DTF transfers tend to be lower in the long run. The speed and efficiency of DTF printing contribute to diminished production time and reduced labor costs, enabling print service providers to fulfill orders more quickly. As consumer preferences shift towards shorter lead times and tailored orders, DTF marking enhances a business’s ability to meet these demands economically.

Sustainability Practices in DTF Printing

Sustainability is no longer a mere option in the textile industry—it has become a necessity. DTF transfers are attractive from a sustainability standpoint, as they utilize inks that often require less water than their traditional counterparts. Moreover, the adaptability of DTF allows manufacturers to minimize waste by applying prints on a wider variety of fabric types. This adaptability not only supports sustainability efforts but also leads to cost savings by reducing raw material waste.

Furthermore, companies are embracing the development of eco-friendly inks that aim to reduce harmful chemicals traditionally associated with textile printing. This shift towards sustainable printing practices is gaining momentum in the industry, encouraging manufacturers to produce high-quality prints while reducing their environmental impact. DTF transfer technology positions itself at the forefront of this change, promising a future where profitability and sustainability can coexist.

Consumer Behavior and the Demand for Custom Apparel

The current consumer landscape showcases an undeniable shift towards personalized experiences, particularly in the realm of fashion. Today’s buyers are inclined to seek out unique pieces that allow them to express their individuality, a trend that has led to an increased reliance on DTF transfers in the production of custom apparel. This increase in demand is reshaping inventory management strategies, pushing retailers to adopt printing methods that accommodate smaller batch sizes more efficiently.

As e-commerce continues to thrive, the need for innovative printing solutions that offer customizability is paramount. DTF transfers provide a rapid and flexible option for businesses to offer bespoke designs without excessive delays or costs. As a result, brands that leverage DTF technology are better positioned to attract and retain consumers looking for tailored fashion statements.

The Future of DTF Transfers in Textile Industry

As we look ahead, the future of DTF printing appears promising, characterized by continuous innovation and adaptation in response to consumer needs. The rise of e-commerce outlets and a growing emphasis on individualism in fashion will likely propel DTF transfers further into the spotlight. Companies that invest in this technology are poised to capitalize on the trend towards on-demand customization, enhancing customer satisfaction and loyalty.

Additionally, as technological advancements continue to drive efficiency and quality improvements in DTF processes, we can expect this printing method to not only compete with traditional approaches but to redefine the standards within the industry. The alignment of DTF technology with sustainability practices, coupled with the strategic initiatives of businesses to innovate and engage consumers, suggests a dynamic future where DTF transfers will be central to the evolution of textile printing.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, are a textile printing method that allows for the printing of vibrant designs on various fabrics. The process involves printing a graphic onto a special film, applying adhesive powder, and then using heat to transfer the design onto the garment. This technology is favored for its ability to produce detailed images quickly and cost-effectively, making it ideal for custom apparel.

Why is DTF printing considered more sustainable than traditional textile printing methods?

DTF printing is recognized for its sustainability due to lower water usage compared to traditional dye-sublimation processes and its ability to work on a wider range of fabrics, minimizing waste. The development of eco-friendly inks that contain fewer harmful chemicals also aligns DTF technology with current sustainability trends in the textile industry.

How does DTF transfer technology contribute to the latest textile printing trends?

DTF transfer technology is at the forefront of textile printing trends, enabling quicker turnarounds for custom designs and small batch orders. This flexibility appeals to the surge in demand for personalized apparel, driving innovation in the industry as businesses aim to meet evolving consumer preferences in fashion.

What advancements in textile printing technology enhance DTF transfers?

Recent advancements in textile printing technology have improved the output quality and speed of DTF transfers. Innovative ink formulations and modern printers allow for stunning color accuracy and durability, making DTF a competitive alternative to traditional printing techniques in the market.

Are DTF transfers suitable for all types of fabrics?

Yes, DTF transfers are versatile and can be applied to various fabric types, including cotton, polyester, and blends. This adaptability makes DTF technology an excellent choice for custom apparel brands seeking to offer a wide range of products without compromising on print quality.

What should businesses consider when adopting DTF transfers for their textile printing needs?

When adopting DTF transfers, businesses should consider factors such as initial setup costs, the versatility of ink formulations, production speed, and the ability to meet consumer demand for personalization. Additionally, staying updated on sustainability practices and integrating eco-friendly inks can enhance their market appeal.

| Key Points | Details |

|---|---|

| Technological Advancements | Enhanced efficiency and quality, versatile applications across fabrics, superior print durability. |

| Cost Efficiency and Accessibility | Lower startup costs reduce barriers for small businesses, ideal for custom apparel and small batch orders. |

| Sustainability Factors | Uses less water compared to traditional methods, development of eco-friendly inks aligns with sustainability goals. |

| Consumer Trends and Demand | Growing demand for personalization, rapid output capabilities cater to e-commerce consumers. |

| Industry Adoption and Market Growth | Significant growth expected as businesses transition to DTF, a strategic advantage over traditional methods. |

Summary

DTF transfers are transforming the textile printing landscape through their rapidity, quality, and environmental sustainability. As this technology continues to evolve, it meets the growing consumer demand for personalized and unique designs while maintaining cost efficiency. With the textile industry increasingly focusing on sustainable practices, DTF transfers showcase their potential not just as a printing method but as a pivotal movement in the future of fashion and apparel. Brands adopting DTF technology are likely to flourish, ensuring they meet the changing demands of an ever-more discerning consumer base.