DTF transfers, short for Direct to Film transfers, have emerged as a game-changer in the world of custom apparel. With the ability to produce vibrant, high-quality prints, they offer unparalleled durability that resonates with both creators and consumers alike. When choosing DTF transfers, it’s essential to understand their advantages compared to other printing methods, ensuring you select the best option for your specific needs. By focusing on DTF transfer quality and sourcing from reputable DTF transfer suppliers, you can enhance the overall customer experience of your products. Whether you are a beginner or a seasoned expert in the custom apparel market, mastering the art of DTF transfers can elevate your offerings significantly.

Exploring alternative methods like Direct to Film prints allows custom apparel creators to harness the benefits of advanced transfer technology. These innovative printing techniques enable the application of intricate designs and bold colors onto various fabrics with remarkable clarity. For designers and business owners alike, understanding the nuances of selecting the right transfer method is crucial for achieving outstanding results. Additionally, keeping an eye on the output quality and ensuring compatibility with different materials can significantly influence customer satisfaction. As the market for custom apparel evolves, embracing these efficient printing solutions can set your business apart from the competition.

Understanding DTF Transfers: The Key to Custom Apparel Success

DTF transfers, or Direct to Film transfers, are a cutting-edge printing method that allows for vibrant and detailed designs to be transferred onto fabrics. Utilizing a specialized film and high-quality inks, the DTF process not only achieves impressive color accuracy but also creates a durable finish that can withstand repeated washing and wear. This technology has revolutionized the way custom apparel is produced, as it combines aesthetic appeal with practicality, making it a preferred choice for many apparel creators.

By understanding the DTF transfer process, you can position yourself to create stunning custom apparel that stands out in a competitive market. This printing method is particularly effective when used on a variety of fabric types, including cotton and polyester, ensuring versatility in your apparel line. The ability to print intricate designs with precise details means that your custom pieces can reflect your brand’s unique style and personality, which is essential in today’s fashion landscape.

Choosing DTF Transfers: Material Compatibility Matters

When selecting DTF transfers for your custom apparel, the compatibility of the transfer with the intended fabric is a crucial factor. Each fabric type behaves differently under heat and pressure, which can significantly impact the outcome of your transfer. For example, DTF transfers work beautifully on cotton and polyester, but specific formulations are required for sensitive materials such as silk or nylon to prevent damage during application.

Ensuring that the DTF transfers you choose are suited for your fabric type will not only enhance the overall appearance but also increase the longevity of the design. Therefore, it is essential to consult product specifications and guidelines to ensure the right match. This attention to compatibility is a fundamental step in achieving high-quality results in your custom apparel line.

Evaluating DTF Transfer Quality: Why It Matters

The quality of DTF transfers you select has a direct impact on the final appearance and durability of your custom apparel. Investing in high-quality transfers means choosing ones made with top-tier inks and durable transfer paper, which directly contributes to a product’s longevity. Cheaper alternatives may seem appealing, but they often result in fading and cracking after only a few washes, ultimately harming your brand’s reputation.

One of the best practices is to seek out reputable DTF transfer suppliers known for their quality guarantees. Suppliers that place importance on product excellence typically offer a range of options, catering to diverse design requirements and fabric types. By prioritizing quality in your transfer selections, you ensure that your custom apparel not only looks great upon delivery but continues to impress customers even after extensive use.

DTF Transfer Adhesive Properties: Essential for Longevity

The adhesive properties of DTF transfers play a vital role in the longevity and appearance of your custom apparel. A strong adhesive ensures that the printed design adheres properly to the fabric, mitigating the risk of peeling or chipping over time. When evaluating DTF transfers, look for those specifically marketed for their adherence capabilities, as this will guarantee that your designs hold up under regular wear and laundering.

A transfer with inferior adhesion not only affects the visual appeal of the apparel but can also lead to increased return rates and customer dissatisfaction. Ensuring that you choose high-quality DTF transfers with proven adhesive strength will help maintain the integrity of your custom apparel and safeguard your business’s reputation among clients.

The Importance of Design Complexity in DTF Transfers

When planning your custom apparel designs, the complexity of your artwork is a significant consideration in selecting DTF transfers. Intricate designs require transfers that can accurately replicate fine details and gradients for the best visual effect. Some DTF transfers are engineered specifically for high-resolution outputs, making them ideal for artistic applications.

Choosing the right transfer for complex designs minimizes the risk of compromising the artwork during the application process. By ensuring that your DTF transfer can handle the intricacies of your designs, you can deliver stunning custom apparel that resonates with your target audience. Strong performance in complex design reproduction is essential to maintaining your brand’s quality and artistic reputation.

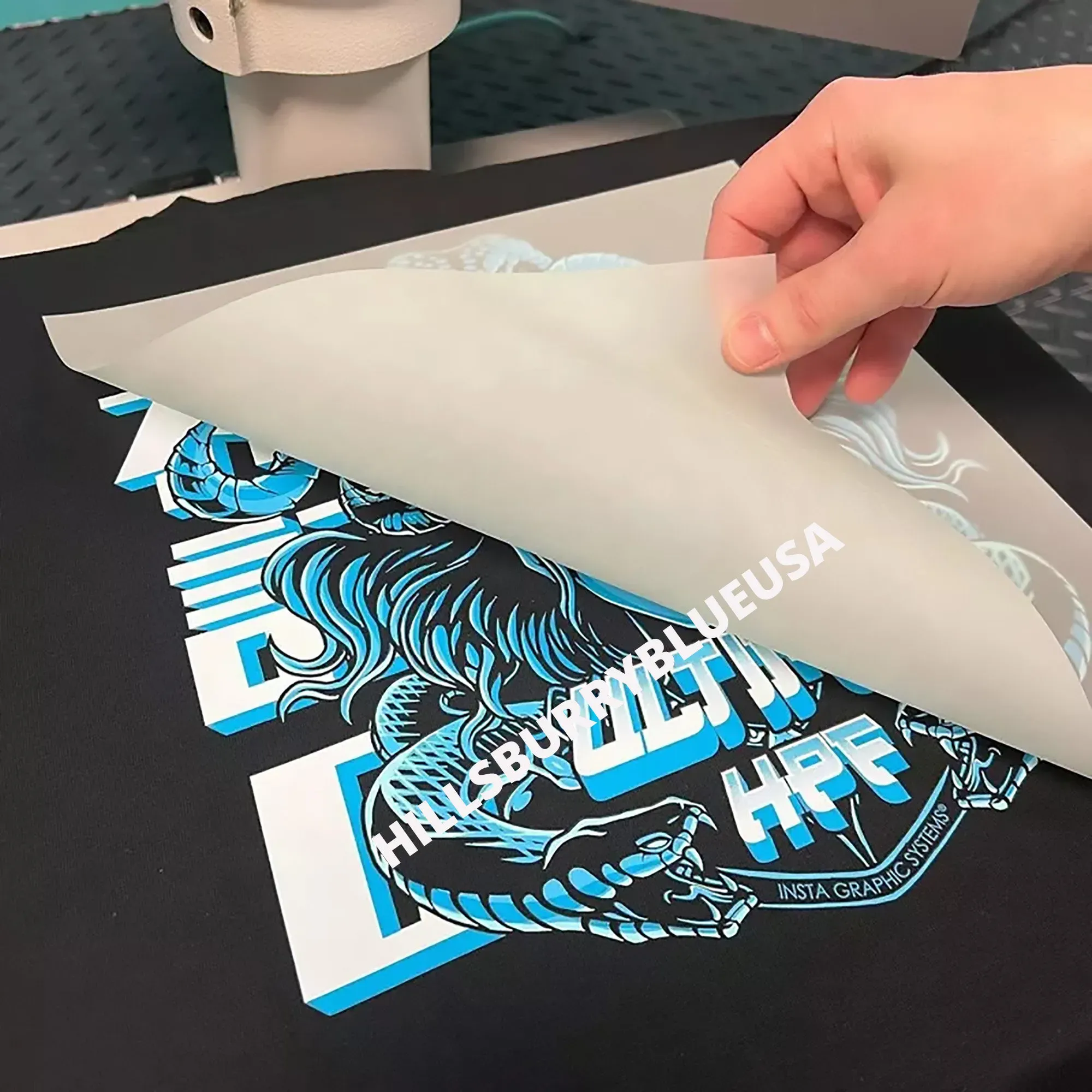

Navigating the Application Process for DTF Transfers

Successfully applying DTF transfers to fabric hinges on a thorough understanding of the application process. This requires familiarity with heat press settings—including temperature, time, and pressure—to achieve the optimal transfer results. Each manufacturer typically provides specific guidelines, and adhering to these is crucial for ensuring high-quality application.

Investing time in mastering different heat press machines and their settings will lead to consistent results and minimize the risk of errors. A well-executed application process not only enhances the quality of your custom apparel but also streamlines your production workflow, making it easier to meet customer expectations and adhere to deadlines.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct to Film transfers, are an advanced printing technique that allows you to apply designs onto fabrics. This process involves printing your design on a special film, which is then transferred to the fabric using heat and pressure. DTF transfers are renowned for their vibrant colors and durability, making them ideal for creating high-quality custom apparel.

How do I choose the right DTF transfers for my custom apparel?

When choosing DTF transfers for custom apparel, consider factors like fabric compatibility, print quality, adhesive properties, and design complexity. Ensure you select DTF transfers that work well with your garment’s material, have high-quality inks for better durability, possess strong adhesive properties, and can accommodate the intricacies of your designs.

What are the advantages of using DTF transfers for custom clothing?

The advantages of DTF transfers include producing vivid, detailed designs that are resistant to fading and cracking, even after multiple washes. They offer versatility across various fabric types and account for intricate designs, making them a smart choice for producing long-lasting custom apparel.

Where can I find reputable DTF transfer suppliers for my custom apparel business?

To find reliable DTF transfer suppliers, research companies with positive reviews and strong customer testimonials. Look for suppliers known for their high-quality products, transparency in pricing, and excellent support services. Online platforms and trade shows dedicated to the custom printing industry often showcase reputable DTF transfer suppliers.

What should I look for in the quality of DTF transfers?

When assessing DTF transfer quality, focus on factors such as the type of inks used, the durability of the transfer paper, and adhesion strength. High-quality DTF transfers will not fade or crack easily and should adhere well to various fabric types, ensuring your custom apparel maintains its appearance even after many uses and washes.

How can advancements in DTF printing technology benefit my custom apparel designs?

Advancements in DTF printing technology can enhance your custom apparel through improved quality and efficiency. Innovations like eco-friendly inks and faster printing processes can provide vibrant results while also reducing environmental impact. Staying updated with the latest trends in DTF transfers allows your designs to leverage cutting-edge techniques for superior customer satisfaction.

| Key Considerations | Details |

|---|---|

| Material Compatibility | Ensure compatibility with fabric types (cotton, polyester, silk, etc.) to avoid damage. |

| Quality of Printing | Select high-quality inks and durable paper to resist fading and cracking. |

| Adhesive Properties | Choose transfers with strong adhesion to prevent peeling or chipping. |

| Design Complexity | Select transfers that can handle intricate designs and high-resolution outputs. |

| Application Process | Follow manufacturer guidelines for heat press settings closely. |

| Cost Considerations | Balance affordability with quality; lower costs can lead to poor results. |

| Supplier Reputation | Research suppliers for reviews and reliability to ensure consistent quality. |

| Innovations and Trends | Stay updated on industry trends for eco-friendly and efficient technologies. |

Summary

DTF transfers are essential for anyone looking to create vibrant and durable custom apparel. By carefully considering factors such as material compatibility, printing quality, and supplier reputation, you can make informed choices that lead to stunning results. Investing in high-quality DTF transfers ensures your designs not only look great but also withstand the test of time, helping your products stand out in a competitive market. Keeping abreast of innovations in the DTF transfer industry will further enhance the quality and efficiency of your custom printing endeavors.