In the dynamic realm of custom printing, the DTF Gangsheet Builder has emerged as a groundbreaking solution that enhances print efficiency and maximizes productivity. This innovative tool allows users to create gang sheets, enabling the simultaneous printing of multiple designs on a single sheet of film, which significantly reduces waste and increases output. With Direct-to-Film (DTF) technology gaining traction, integrating a DTF Gangsheet Builder into your printing operations can streamline processes and elevate the quality of your prints. By harnessing this powerful printing technology, businesses are not only optimizing their resources but also meeting the growing demand for high-quality, custom prints. This article delves into the features of DTF gangsheet builders, recent advancements in DTF printing, and best practices to ensure you make the most out of your investment in custom printing solutions.

As the world of printing transforms, concepts like film transfer technology and sheet layout automation are becoming increasingly significant. The DTF Gangsheet Builder serves as a pivotal interface that enables printing businesses to produce multiple designs simultaneously in a cost-effective manner. This approach not only enhances print productivity but also caters to a diverse array of needs in custom design applications. The rising popularity of gang sheets as a sustainable printing method highlights the importance of efficient layout techniques and optimized materials in today’s market. By exploring these advanced printing solutions, companies can stay competitive in a rapidly changing industry.

Maximizing Print Efficiency with DTF Technology

DTF printing technology is designed to boost print efficiency significantly. By implementing the Direct-to-Film method, businesses can streamline their printing processes. Unlike traditional methods that generally require multiple steps and materials, DTF allows printers to directly transfer vibrant designs onto fabrics in one seamless process. This not only saves time but also reduces the consumption of resources — ink and film are used more judiciously, cutting down on waste.

Additionally, employing DTF technology helps printers capitalize on print efficiency by enabling quicker turnaround times. With advanced machinery now capable of high-speed output, businesses can manage larger orders without a compromise in quality. This speed can be particularly beneficial in today’s fast-paced market, where customers often demand rapid fulfillment coupled with impressive design quality.

The Advantages of Using DTF Gangsheet Builder

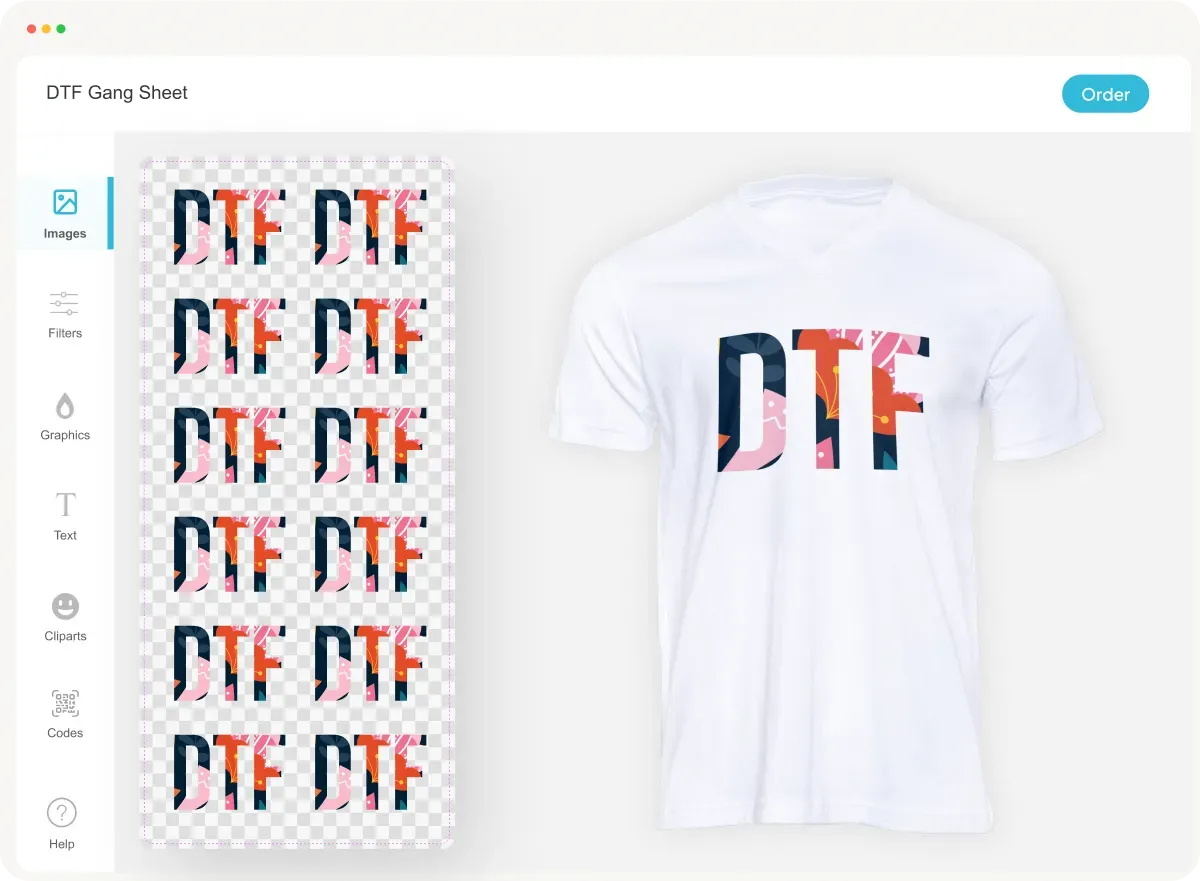

The DTF Gangsheet Builder is a powerful tool that revolutionizes the printing process. By enabling the arrangement of multiple designs on a single sheet of film, businesses can maximize the use of materials while minimizing excess. This optimization not only leads to cost savings but also aligns with environmentally friendly practices, making the DTF printing method more sustainable than many alternatives.

Moreover, the user-friendly interfaces of contemporary DTF Gangsheet Builder software simplify the creation process. Features such as auto-alignment and resizing options streamline the workflow, allowing print providers to position designs efficiently. This accessibility enables even novice users to leverage the full potential of DTF printing technology, producing high-quality outputs with ease.

Recent Advancements in DTF Printing Technology

The realm of DTF printing is witnessing significant advancements that are pushing the boundaries of what printers can achieve. Recent innovations in machinery and software solutions have emerged, enhancing automated capabilities in layout design and printing operations. This progress minimizes the incidence of human error and expedites the entire process, thus improving overall print quality and increasing output volume.

Additionally, the emergence of specialized software tools for gangsheet creation simplifies the arrangement and alignment of graphics. Features that allow for quick auto-layout and template options further optimize the printing experience. These advancements not only speed up production times but also cater to the growing demand from businesses seeking efficiency in custom printing solutions.

Best Practices for Effective DTF Gangsheet Printing

To harness the full potential of DTF gangsheet builders, adherence to best practices is essential. For instance, it is crucial to adhere to recommended size limitations for artwork files. Doing so helps ensure that the prints remain consistent and are free from inaccuracies that can arise from oversized graphics. This proactive approach can prevent costly errors and reprints, maximizing both time and resources.

Another vital best practice is proper machine calibration. Regular calibration helps maintain color accuracy and ensures quality prints. This routine check allows businesses to predict outcomes effectively, eliminating discrepancies that could arise during production. Additionally, conducting test prints can save both time and resources, allowing for adjustments before committing to full-scale runs.

Understanding the Market Trends in DTF Printing

Understanding current market trends around DTF printing is crucial for businesses aiming to stay competitive in the industry. The growing popularity of e-commerce and custom apparel has significantly fueled the demand for efficient printing solutions. As more customers seek personalized products, print providers are increasingly adopting DTF technology to meet these evolving needs efficiently.

Moreover, with advancements in DTF printing, operators now have access to affordable solutions that reduce operational costs while improving quality. This shift in market dynamics has encouraged small and medium-sized businesses to invest in DTF technology, positioning themselves to capitalize on the burgeoning custom printing market.

Future Innovations in DTF Printing

The future of DTF printing looks promising, with continuous innovations on the horizon. As the technology advances, we expect further improvements in print quality, speed, and resource efficiency. With emerging trends indicating a demand for versatile and eco-friendly printing solutions, manufacturers are likely to invest more in developing advanced materials and high-performance inks that enhance the DTF printing capabilities.

In addition, integration with Artificial Intelligence (AI) and Machine Learning (ML) technologies could revolutionize how DTF printing operates. These advancements could enable predictive analytics to help production facilities anticipate demand patterns and optimize equipment performance for maximum efficiency. Such innovations will define the next era of DTF printing, providing businesses with unprecedented levels of control and productivity.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is specialized software that optimizes the process of printing multiple designs on a single sheet using Direct-to-Film (DTF) technology. By enabling the arrangement of gang sheets, it helps maximize print efficiency, reduce material waste, and streamline overall production.

How does the DTF Gangsheet Builder improve printing efficiency?

The DTF Gangsheet Builder significantly improves printing efficiency by allowing multiple designs to be printed simultaneously on one film sheet. This not only conserves resources and minimizes waste but also accelerates the production process, making it ideal for businesses looking to enhance their DTF printing operations.

Can beginners easily use the DTF Gangsheet Builder?

Yes, many DTF Gangsheet Builder software options, such as ‘DTF Pro’ and ‘Gang Sheet Builder Pro,’ are designed to be user-friendly. With intuitive interfaces and customizable features, beginners can easily learn how to create and optimize gang sheets for their printing needs.

What are the environmental benefits of using a DTF Gangsheet Builder?

Using a DTF Gangsheet Builder reduces environmental impact by minimizing waste associated with printing. Since it allows for multiple designs to be printed on a single sheet, there is less film and ink waste compared to traditional printing methods, making it a more sustainable option.

What recent advancements in DTF technology enhance the use of Gangsheet Builder?

Recent advancements include sophisticated printing machines that automate gang sheet layouts and specialized software for arranging designs. These innovations streamline processes and improve print quality and speed, making the DTF Gangsheet Builder even more effective for modern print businesses.

What best practices should I follow when using a DTF Gangsheet Builder?

To achieve optimal results with a DTF Gangsheet Builder, follow best practices such as adhering to size limitations for artwork, calibrating your printing machines regularly, using high-resolution designs, and conducting test prints to address any potential issues before full production.

| Key Points | Details |

|---|---|

| Introduction | DTF technology is transforming custom printing, particularly through the DTF Gangsheet Builder for efficiency and waste reduction. |

| Understanding DTF Printing | DTF printing transfers images to fabric using a film layer, known for cost-effectiveness, speed, and quality. |

| Role of DTF Gangsheet Builder | Software designed to create gang sheets with multiple designs, maximizing efficiency and reducing material waste. |

| Key Benefits | 1. Maximized Efficiency 2. User-Friendly Software 3. Environmentally Friendly 4. High-Speed Production |

| Recent Developments | 1. Technological Innovations 2. Emergence of Software Tools 3. Market Growth Trends 4. User Feedback and Improvements |

| Best Practices | 1. Adhere to Size Limitations 2. Calibration is Key 3. Use High-Quality Designs 4. Test Prints |

Summary

The DTF Gangsheet Builder is revolutionizing the printing industry by enabling businesses to enhance their productivity and efficiency through advanced technology and best practices. This innovative tool not only consolidates designs on a single film sheet but also contributes to a sustainable approach to printing. By adopting the DTF Gangsheet Builder, companies can significantly reduce material waste, lower costs, and improve print quality, thus positioning themselves favorably in a competitive market. For those looking to optimize their printing operations, exploring the functionalities and advantages of the DTF Gangsheet Builder is essential.