In the realm of custom apparel and innovative printing solutions, the DTF Gangsheet Builder stands out as a revolutionary tool that redefines efficiency in the industry. This advanced method of Direct-to-Film (DTF) printing presents numerous benefits over traditional printing methods, allowing businesses to create high-quality designs with minimal waste. By utilizing DTF gang sheets, companies can streamline their production processes and significantly cut down on turnaround times, making it an ideal choice for those looking to optimize their custom apparel printing endeavors. Furthermore, this printing technology comparison reveals how DTF revolutionizes the approach to multi-design printing, setting a new standard for versatility and vibrancy in apparel production. As the demand for detailed, colorful, and efficient printing grows, the DTF Gangsheet Builder ensures that businesses are equipped to meet these challenges with ease.

As the custom apparel landscape evolves, understanding the intricacies of the DTF Gangsheet Builder is crucial for any forward-thinking business. Known also as Direct-to-Film gang sheets, this modern printing technique offers an array of advantages over conventional methods such as screen printing and heat transfer. With its ability to produce multiple designs on a single film sheet, DTF printing provides unique benefits that include reduced waste and improved efficiency. Companies are increasingly turning to this advanced printing method due to its outstanding quality and adaptability across various materials. In this discussion, we delve deeper into the effectiveness of DTF printing relative to traditional approaches, exploring how this innovative technology shapes the future of custom apparel.

Understanding DTF Gangsheet Builder

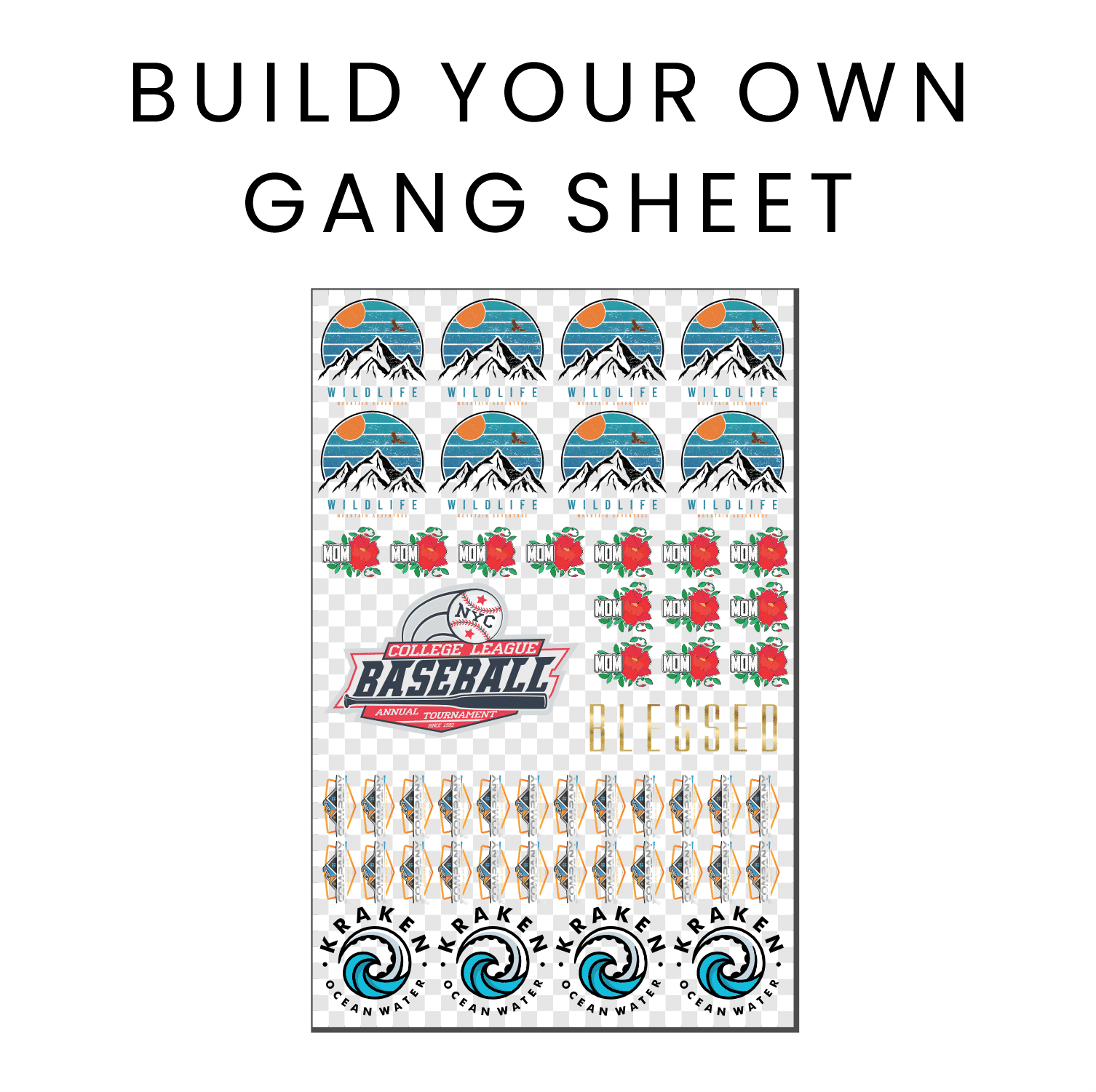

The DTF Gangsheet Builder is a revolutionary tool that allows custom apparel businesses to maximize efficiency by organizing multiple designs on a single film sheet. This method optimizes the use of materials, minimizing waste and reducing costs. By assembling various graphics into one gang sheet, printers can achieve extensive production runs without the hassle of setting up individual prints, leading to higher throughput and lower overall expenses.

Additionally, the flexibility offered by the gang sheet method enables businesses to experiment with diverse designs and colors while still maintaining a streamlined production process. This approach is especially beneficial for enterprises with high volume demands or those catering to specific marketing needs, where multiple designs are required on short notice.

Frequently Asked Questions

What advantages does the DTF Gangsheet Builder offer over traditional printing methods?

The DTF Gangsheet Builder provides several advantages over traditional printing methods, including significantly faster production times due to the ability to print multiple designs on a single sheet. This method also reduces material waste, allowing businesses to optimize their printing processes. Additionally, DTF printing produces high-quality outputs with vivid colors and intricate details that are often challenging to achieve with traditional methods.

How does DTF printing reduce waste compared to traditional printing?

DTF printing reduces waste by utilizing gang sheets, which allow several designs to be printed simultaneously on a single film sheet. This method minimizes the leftover material that typically occurs with traditional printing methods, where individual setups are needed for each design, leading to higher waste from misprints or surplus materials.

Is the DTF Gangsheet Builder suitable for all fabric types?

Yes, the DTF Gangsheet Builder is highly versatile and is suitable for a wide range of fabric types, including cotton, polyester, blends, and synthetic materials. This adaptability makes DTF printing an ideal choice for businesses looking to offer diverse custom apparel options and expand their product line.

What are the initial costs associated with adopting the DTF Gangsheet Builder?

While the initial investment in DTF equipment, including printers, inks, and films, may be higher than traditional printing methods, many businesses find that the increased efficiency and productivity from using the DTF Gangsheet Builder allow them to recoup these costs over time through decreased waste and faster order fulfillment.

How does DTF printing compare to traditional methods in terms of print quality?

DTF printing typically outperforms traditional methods in print quality. With advanced technology, DTF printers can produce vibrant colors and fine details that traditional techniques, such as screen printing, may struggle to achieve. This ability to deliver high-quality outputs is a primary reason why many businesses are shifting toward DTF printing for their custom apparel needs.

What is the learning curve associated with the DTF Gangsheet Builder?

The DTF Gangsheet Builder does come with a learning curve as staff need training to effectively use the DTF printers and optimize print settings. However, the quality and efficiency benefits often outweigh the initial difficulties. With time and practice, many users find that mastering DTF printing techniques leads to high-quality results and improved production capabilities.

| Aspect | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Definition | Technique printing multiple designs on one film sheet, optimizing the process and reducing waste. | Involves individual setups per design, often leading to longer production times. |

| Efficiency | Allows simultaneous printing of various designs, which cuts down production time significantly. | Extended setup times lead to increased waste and reduced speed. |

| Quality of Prints | Produces vibrant, detailed prints with a wide color range. | Quality can be decent but may lack fine detail and color variety. |

| Versatility | Compatible with a wide range of fabrics, enhancing product offerings. | Limited to specific materials, reducing product variety. |

| Cost Considerations | Higher initial investment, but cost-effective in the long run through increased productivity. | Lower initial costs, but typically less efficient and more wasteful over time. |

| Learning Curve | Requires training on specific equipment and settings for optimal results. | More familiar to many operators, but can hinder adopting new technologies. |

Summary

The DTF Gangsheet Builder stands out as a revolutionary solution in modern printing technology, streamlining processes and enhancing customization options for businesses in the apparel industry. By combining multiple designs onto a single film sheet, the DTF Gangsheet Builder not only saves time but also minimizes material waste, offering a significant advantage over traditional printing methods. With its ability to produce high-quality prints on a variety of fabrics efficiently, DTF printing is rapidly becoming the preferred choice for many custom apparel businesses. As the demand for innovative and versatile printing solutions grows, adopting tools like the DTF Gangsheet Builder enables companies to remain competitive and responsive to their customers’ needs.