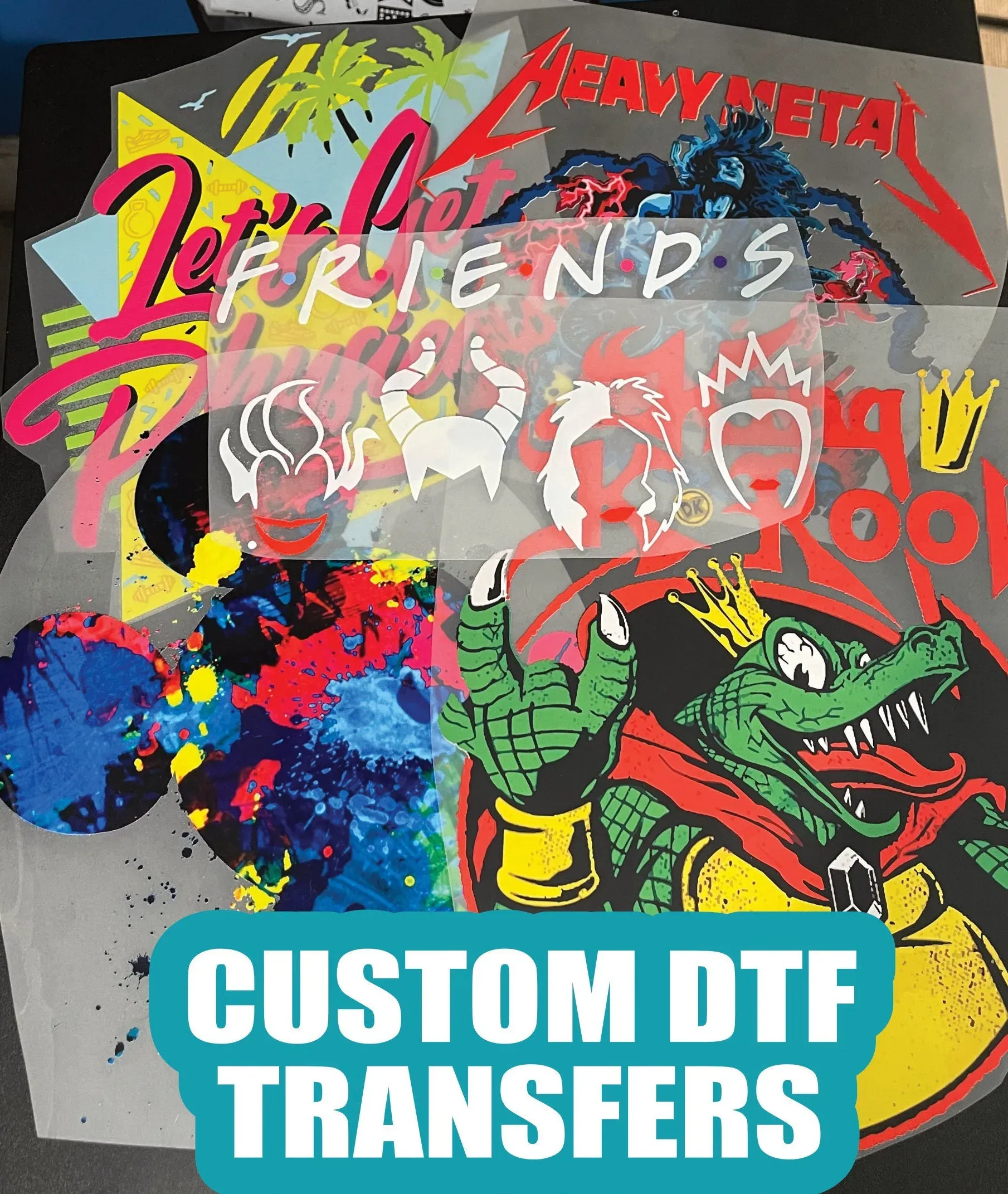

DTF Transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom apparel printing. This innovative method stands out among various garment printing techniques, such as screen printing and direct-to-garment (DTG) printing, due to its incredible efficiency and vibrant results. Unlike traditional heat transfer vinyl (HTV), DTF transfers allow for intricate designs that can be applied to a wide variety of fabrics. As entrepreneurs and businesses seek high-quality solutions for custom apparel, DTF printing emerges as a highly versatile option that balances both creativity and cost-effectiveness. Understanding the nuances of DTF transfers is crucial for making informed decisions in today’s diverse printing market.

Direct-to-Film (DTF) printing serves as a modern alternative in the realm of garment decoration, appealing to those who wish to explore the world of custom clothing. Often compared to more established techniques like direct-to-garment (DTG) and traditional screen printing, DTF allows for vividly detailed designs that cater to various fabric types. Additionally, this printing method integrates seamlessly with applications that use heat transfer technologies, creating an increasingly popular option among producers and consumers alike. By embracing this innovative approach to apparel printing, businesses can tap into a dynamic market and offer unique products that meet consumers’ evolving tastes.

Understanding DTF Transfers and Their Benefits

Direct-to-Film (DTF) transfers have revolutionized the custom printing landscape, providing an efficient and vibrant medium for designers. Unlike traditional printing methods, DTF transfers involve a unique process where designs are printed onto a specialized film rather than directly onto the fabric. This film is then transferred to apparel using heat, allowing for intricate designs and vivid colors that pop on various materials. The versatility of DTF technology is evident as it works flawlessly with cotton, polyester, and even blends, making it a go-to choice for diverse garment printing needs.

The benefits of DTF transfers extend beyond just aesthetics. They also offer a cost-effective solution for businesses, particularly small-scale operations. With lower setup costs compared to screen printing, DTF allows for smaller batch prints without breaking the bank. This approach not only minimizes waste, as businesses can print only what they need, but it also opens the door for more entrepreneurs to enter the custom apparel market. Enhanced durability is another significant advantage, with DTF prints maintaining their vibrant look even after multiple washes, making them ideal for high-quality apparel.

Comparison of DTF Transfers to Screen Printing

When comparing DTF transfers to screen printing, several factors highlight the differences in application and suitability. Screen printing remains a favorite for large production runs due to its traditional processes and established durability. However, it is essential to note that screen printing is best for simpler designs with fewer colors, as each hue requires a separate screen, increasing overall costs and time. This setup makes screen printing less viable for small orders, where artists may seek more versatility and creative freedom.

In contrast, DTF technology shines in scenarios requiring detailed and colorful designs without the logistical constraints of screen printing. DTF enables artists to produce complex images with multiple colors in a single pass, which is particularly appealing for detailed artwork and customizations. As a result, businesses that prioritize vivid graphics and smaller-scale orders may find DTF transfers to be a more efficient and cost-effective solution.

Evaluating DTF Transfers Against Direct-to-Garment Printing

Both DTF and Direct-to-Garment (DTG) printing methods excel in producing high-quality, intricate designs, yet they operate under different mechanics that cater to varying business needs. DTG is particularly well-suited for designs with extensive color variations and fine details, as it prints directly onto the fabric. However, the process can be relatively slow, making it less ideal for bulk orders. It also typically comes with higher initial costs associated with machine setup, which can deter small businesses from opting for this method.

On the other hand, DTF transfers allow for more rapid production cycles without compromising quality. This method is advantageous for businesses needing to manage tight deadlines while still offering customized options. Additionally, DTF’s adaptability to various fabric types provides a competitive edge, making it a more versatile choice for apparel lines looking to expand their design offerings without significant upfront investments.

Heat Transfer Vinyl vs. DTF Transfers: A Detailed Look

Heat Transfer Vinyl (HTV) is another popular method for custom apparel printing, cherished for its simplicity and effectiveness in small-scale projects. However, when compared to DTF transfers, HTV presents some limitations, particularly regarding the color gradient and design complexity. While HTV can produce vibrant prints, the need for layering colors can lead to labor-intensive processes, especially when dealing with intricate designs. This often makes HTV less appealing for those looking to produce high-quality graphics at scale.

DTF transfers, with their direct printing onto film, minimize these complexities. They allow for easier production of detailed graphics and complex color schemes without the need for multiple layers. Particularly for fashion-forward designs requiring bright colors and durability, DTF presents a significant advantage over HTV, making it a favored choice among designers and small business owners alike.

Key Considerations for Choosing Your Printing Method

Selecting the right printing method for custom apparel involves careful consideration of various factors, including order size, design intricacy, and fabric type. DTF transfers, for instance, are an excellent choice for smaller orders that require unique, detailed designs due to their moderate setup costs and quick turnaround times. They strike a balance between cost efficiency and quality, allowing startups and individual creators to effectively express their artistic visions without excessive financial burden.

In contrast, when planning for larger production runs or straightforward designs, it might be worthwhile to evaluate screen printing as a more suitable option due to its efficiency for bulk orders. Similarly, if high detail and varied colors are prioritized, direct-to-garment printing may present optimal results despite the higher costs. Recognizing these considerations can direct businesses in making informed decisions that align with their creative and commercial goals.

Current Trends and Innovations in DTF Printing

The landscape of DTF printing is evolving with recent trends focusing on sustainability and technological advancements. Many manufacturers are integrating eco-friendly inks into their processes, responding to the escalating demand for environmentally responsible practices in custom apparel production. This shift not only allows for vibrant, high-quality prints but also aligns with consumer preferences for sustainable products, appealing to a growing market segment.

Innovations in DTF technology have also made these systems more accessible to small businesses, providing them with tools to compete in the rapidly changing apparel industry. Enhanced printing speeds and improved machine efficiency mean businesses can fulfill larger orders without sacrificing detail or quality. Embracing these advancements ensures that businesses remain competitive while adapting to contemporary market demands in the custom printing sector.

Frequently Asked Questions

What are DTF transfers and how do they compare to screen printing?

DTF transfers, or Direct-to-Film transfers, are a modern garment printing method that involves printing designs onto a special film and then applying them to fabric using heat. Unlike screen printing, which requires extensive setup and is ideal for large orders, DTF transfers are cost-effective for small batches and allow more detailed and colorful designs.

Are DTF transfers better than direct-to-garment printing?

DTF transfers can be considered better than direct-to-garment (DTG) printing for smaller orders due to their lower setup costs and versatility with various fabric types. While DTG excels in intricate designs with complex colors, DTF offers vibrant colors and durability, making it an attractive option for custom apparel.

What advantages do DTF transfers have over heat transfer vinyl (HTV)?

DTF transfers outperform heat transfer vinyl (HTV) in terms of color detail and gradient capabilities. While HTV is suitable for small projects, it can become labor-intensive and less effective for intricate designs. DTF transfers deliver vibrant, detailed results without the extensive manual work involved in HTV.

How durable are DTF transfers compared to other garment printing methods?

DTF transfers are known for their durability, maintaining quality even after multiple washes, similar to screen printing. While screen printing may offer a thicker ink layer, DTF transfers still provide long-lasting results that withstand wear over time, making them suitable for custom apparel.

What type of fabrics work best with DTF transfers?

DTF transfers are incredibly versatile and can be used on various fabric types, including cotton, polyester, and blends. This adaptability makes DTF printing a favored option for custom apparel across different products, from t-shirts to bags, allowing for a wide range of applications.

Can I integrate DTF transfers into my custom apparel printing business?

Integrating DTF transfers into your custom apparel printing business can be highly beneficial. This method offers cost-effectiveness for small orders, vibrant print quality, and compatibility with numerous fabric types. As consumer demand for unique designs grows, DTF transfers can enhance your business’s offering in the competitive market.

| Feature | DTF Transfers | Screen Printing | Direct-to-Garment (DTG) | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Versatility | Compatible with a wide variety of fabrics (cotton, polyester, blends) | Best for large orders, limited color variations | Excels in intricate designs, suitable for bulk | Great for small projects, limited detail and colors |

| Cost-Effectiveness | Affordable for small batches; lower setup costs | High setup costs make it less economical for small runs | Higher initial costs, needs mass production to be cost-effective | Cost-efficient for single designs or small orders |

| Color and Detail | Produces vibrant colors and intricate details | Limited to fewer colors; best for basic designs | Ideal for complex color schemes and fine details | Labor-intensive for detailed designs and lacks gradient |

| Durability | Resistant to wear and lasts through washes | Considered more durable due to thicker inks | Slower production turnarounds can affect durability | Can degrade over time; less durable than DTF |

Summary

DTF Transfers represent a pivotal advancement in the realm of custom apparel, offering a versatile and cost-effective solution for creative designs. As illustrated in the table, DTF stands out for its compatibility across various fabric types and its ability to produce vibrant colors with intricate details. It serves particularly well for small to medium-sized businesses aiming to deliver quality products without the high costs typically associated with traditional methods like screen printing and DTG. In summary, understanding DTF Transfers will empower your decision-making in selecting the right printing method tailored to your specific needs.