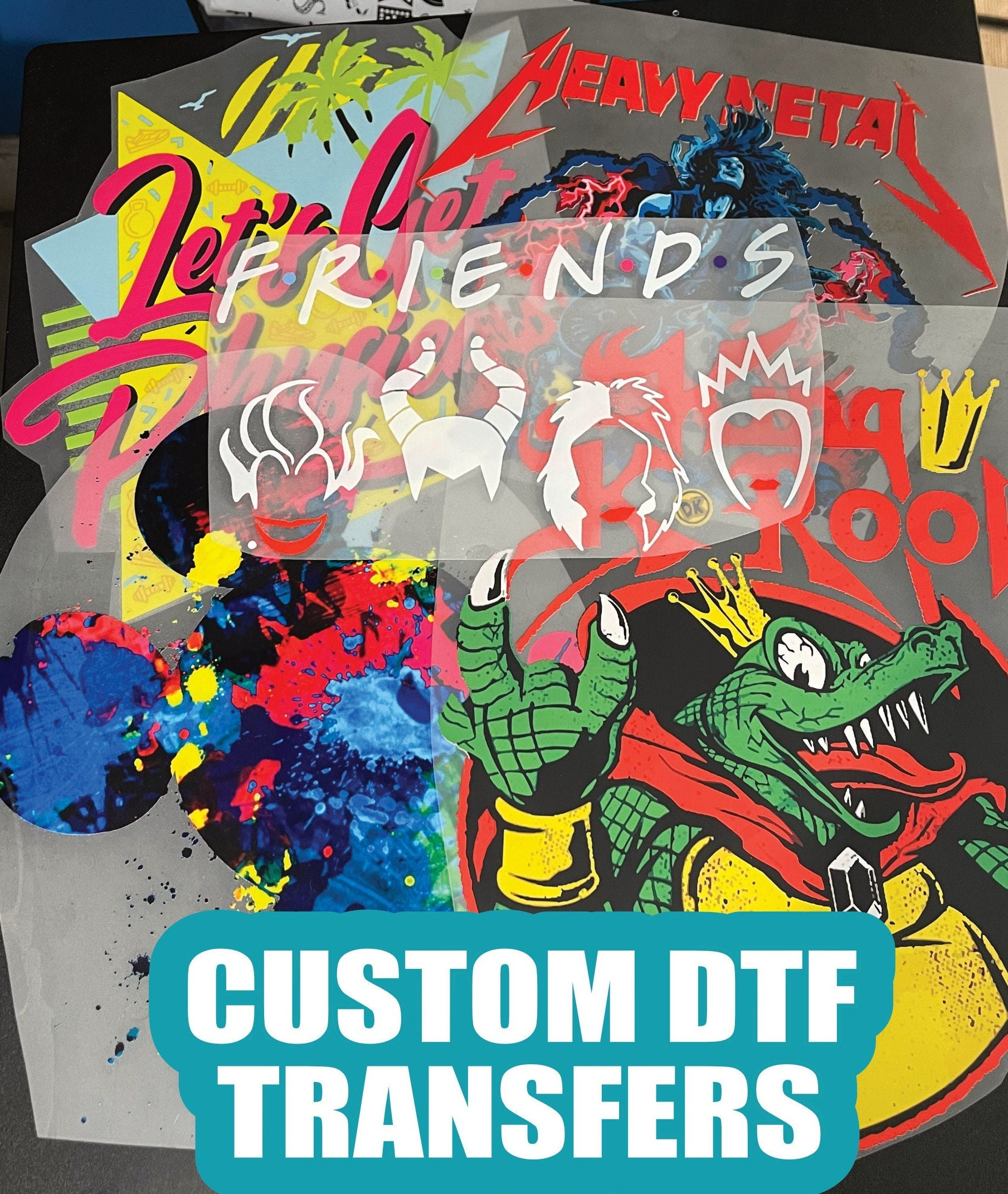

DTF transfers, or Direct-to-Film transfers, represent a revolutionary breakthrough in the garment printing industry. This cutting-edge printing technology combines exceptional image quality with remarkable versatility, allowing for vibrant designs to be transferred onto a variety of fabrics, making it an attractive option for both DIY enthusiasts and professional garment decorators. In this article, we will explore how DTF transfers work, examining the intricate process behind this popular method and why it has gained a loyal following among textile printers. With a focus on the advantages of DTF printing, including cost-effectiveness and durability, we are set to uncover what makes it a favored choice in today’s competitive market. Join us as we delve into the fascinating world of DTF transfers and uncover the secrets behind their growing popularity.

Also referred to as direct-to-film printing, this innovative method thrives on the ability to create stunning, high-quality graphics that adhere seamlessly to various textile surfaces. By utilizing specialized films and adhesives, this garment printing technique allows users to achieve detailed designs that are both eye-catching and durable. As the demand for personalization in fashion rises, understanding how these transfers operate opens new opportunities for creators and businesses alike. With its flexibility to print on cotton, polyester, and blends, the technique has quickly become a go-to solution in the realm of garment decoration. This exploration of direct-to-film transfers highlights not just a printing method, but a transformative approach to how garments can be customized.

Understanding DTF Transfers

DTF transfers, or Direct-to-Film transfers, represent a significant innovation in the garment printing universe. This technology allows for the direct application of high-resolution designs onto specialized films, which can then be applied to various textile substrates through heat activation. By using a DTF printer that applies specific inks, the images become vibrant and can accurately reflect the intricacies of the design. As a result, both professional printers and hobbyists can achieve a level of detail and color fidelity that was previously challenging to obtain.

The versatility of DTF transfers extends to an array of fabric types, including cotton, polyester, and blends. Unlike traditional printing methods, which are often limited to specific materials, DTF technology expands creative possibilities for designers looking to apply detailed graphics to various surfaces. This adaptability is crucial for businesses targeting a broad audience with diverse garment needs, making DTF an attractive option in today’s competitive market.

How DTF Transfers Work: A Closer Look

The process of DTF transfers involves multiple steps, starting from the initial image design to the final application on textiles. Initially, designers utilize graphic design software like Adobe Illustrator or CorelDRAW to create a high-resolution image. Once finalized, the design is printed onto a special DTF film using high-quality inks. This initial step is critical as the fidelity of the print directly influences the final output on the garment.

Following the printing phase, an adhesive powder is applied to the wet ink, which then requires curing. This step ensures that the adhesive properly binds to the printed image, readying it for the transfer process. Finally, the heat press method is used to apply the film to the fabric, activating the adhesive and securing the design to the textile. The effectiveness of this method can be seen in the quality and durability of the prints, cementing DTF’s reputation as a favorable garment printing technology.

DTF Printing Advantages Over Traditional Methods

There are several advantages of DTF printing that contribute to its growing popularity. Firstly, the ability to print on a wide variety of fabric types without compromising quality means that businesses can cater to a diverse customer base. While traditional screen printing may limit options based on fabric composition, DTF technology allows seamless adaptability across textiles, enhancing production flexibility.

Additionally, the cost-effectiveness of DTF transfers is another important factor. For smaller production runs, DTF printing tends to incur lower initial setup costs, making it an attractive option for entrepreneurs looking to minimize waste and maximize profit margins. This means that businesses can produce custom prints on-demand, reducing inventory costs and allowing for greater creativity in their product offerings.

Recent Innovations Shaping DTF Technology

Innovations within the DTF printing sector have led to enhanced operational capabilities and broadened service offerings. Companies like Snuggle have introduced commercial-grade DTF transfer services that optimize production processes through advanced web-to-print platforms. This transformation is facilitating faster turnaround times, making DTF an even more appealing choice for businesses that require high-volume printing solutions.

Furthermore, brands like EazyDTF are expanding their reach with new large-format DTF printers that promise same-day shipping services. Innovations like these reflect the increasing demand for rapid printing solutions in both crafting and commercial environments. These advancements not only improve efficiency but also position DTF as a competitive player in the textile printing market.

Evaluating the Performance of DTF Transfers

As DTF transfers rise in popularity, ongoing evaluations are essential for understanding their long-term viability. Durability is a critical factor in assessing the performance of DTF prints, particularly concerning their resistance to washing and fading. Various tests are underway to gauge how well these prints withstand daily wear and maintain their vibrancy over time.

Equally important is the ability to safely remove DTF transfers, which has become a focus of current research. Understanding how to maintain the integrity of the fabric while effectively removing the transfer will enhance the versatility and user-friendliness of DTF technology. As these insights become available, they will further solidify DTF’s position as a reliable and innovative printing method on the market.

The Future of DTF Transfers in the Garment Industry

Looking forward, the future of DTF transfers appears promising as the technology continues to evolve. With consistent improvements in printing techniques and machinery, companies are poised to refine the quality and efficiency of DTF printing even further. The integration of cutting-edge tools will empower designers and brands to push the boundaries of personalization and customization in garment printing.

Moreover, as consumer demand for unique, high-quality prints grows, businesses will increasingly adopt DTF technology to meet these needs. The flexibility to cater to various styles and preferences enhances the appeal of DTF transfers, positioning them at the forefront of modern garment printing solutions. The combination of quality, adaptability, and evolving technology ensures that DTF will play a pivotal role in the future landscape of the apparel printing industry.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a garment printing technology that involves printing a design onto a special film. This film is then used to transfer the image onto textiles. The process begins with creating an image, printing it on the DTF film, coating it with adhesive powder, and curing it. Finally, the film is applied to the fabric using heat, activating the adhesive to bond the design permanently.

What are the advantages of using DTF printing over other methods?

DTF printing offers several advantages over traditional printing methods. It is more flexible, allowing prints on a variety of fabrics, including cotton and polyester. The prints are high-quality, delivering vibrant colors and fine details. Additionally, DTF transfers are cost-effective for small production runs, require less setup, and enable on-demand printing, reducing inventory costs.

Is DTF printing suitable for commercial use?

Yes, DTF printing is highly suitable for commercial use. Innovations such as Snuggle DTF Service and EazyDTF’s expansion into large format printing have increased production capabilities. These services cater to high demand, allowing businesses to produce a large volume of DTF transfers efficiently, thus meeting the needs of commercial garment decoration.

Can DTF transfers be applied to different types of fabrics?

Absolutely! One of the key benefits of DTF transfers is their versatility. They can be applied to a wide range of fabrics, including cotton, polyester, and various fabric blends. This flexibility makes DTF transfers an attractive option for both crafters and businesses looking to cater to diverse customer preferences.

How durable are DTF transfers after application?

DTF transfers are designed for durability. Current tests are being conducted to assess their resistance to washing and fading over time. The results will help determine the longevity of DTF prints and their overall value for end-users, ensuring a high-quality product that lasts.

What recent innovations are shaping the future of DTF transfers?

Recent innovations in DTF technology include the launch of services like Snuggle DTF, which enhances efficiency for commercial printing, and EazyDTF’s expansion with new large-format printers. These advancements indicate significant growth in the DTF market, as companies adapt to increase production capacity and meet rising consumer demand for quality DTF transfers.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers represent a revolutionary technology in garment printing, favored for its quality, flexibility, and ease of use. |

| What are DTF Transfers? | DTF transfers use a special film to print high-resolution images that are then transferred to textiles using heat. |

| Process of DTF Transfers | The process includes image design, printing on film, curing the adhesive, and the final transfer application. |

| Popularity Factors | Flexibility, high print quality, cost-effectiveness, and ongoing technological advancements contribute to the rise of DTF transfers. |

| Recent Innovations | Launch of Snuggle DTF Service and EazyDTF’s expansion highlight the growing capabilities and efficiency in the DTF printing industry. |

| Testing and Performance | Durability and removability studies are being conducted to assess the long-term value of DTF transfers. |

| Conclusion | DTF transfers are transforming garment printing by delivering quality and versatility, supported by continuous technological improvements. |

Summary

DTF transfers are shaping the future of garment printing with their innovative technology and versatility. As they blend high-resolution printing with the ability to work on various fabrics, they present a unique solution for businesses and hobbyists alike. The adaptability of DTF transfers makes them suitable for a wide range of applications, ensuring vibrant prints that retain quality over time. With ongoing technological advancements and increased commercial applications, DTF transfers continue to solidify their presence in the textile industry, providing creators and businesses with exceptional efficiency and quality in their printing needs.