DTF transfers, or Direct-to-Film transfers, are revolutionizing the way designs are printed onto fabrics. This cutting-edge printing method offers exceptional vibrancy, allowing intricate graphics to be applied seamlessly on a variety of materials, such as cotton and polyester. As businesses and crafters increasingly harness the power of this technology, the need for custom DTF printing solutions has surged, making it a vital player in the apparel sector. Moreover, advances in DTF technology developments highlight its role as one of the most sustainable printing solutions available today, by reducing waste and enhancing print quality. Whether you are an entrepreneur looking to elevate your product line or a hobbyist seeking to create unique pieces, understanding DTF transfer services is essential to your success in the modern printing landscape.

Exploring the realm of Direct-to-Film print technology unveils a world of advanced transfer options that are reshaping fabric printing. Known for its effectiveness in applying vibrant graphics, DTF printing has garnered attention for its ability to cater to diverse materials and fulfill custom design requests. In light of recent sustainability initiatives within the industry, businesses and creators alike are recognizing the importance of eco-friendly printing solutions that can reduce waste. Furthermore, developments in this innovative transfer method have sparked interest in specialized services, allowing for tailored production that meets the growing demands of both vendors and consumers. Engaging with the latest updates in DTF transfer techniques not only showcases the limitless creative possibilities but also emphasizes a commitment to sustainable practices in today’s apparel market.

Understanding DTF Transfers: A Deep Dive

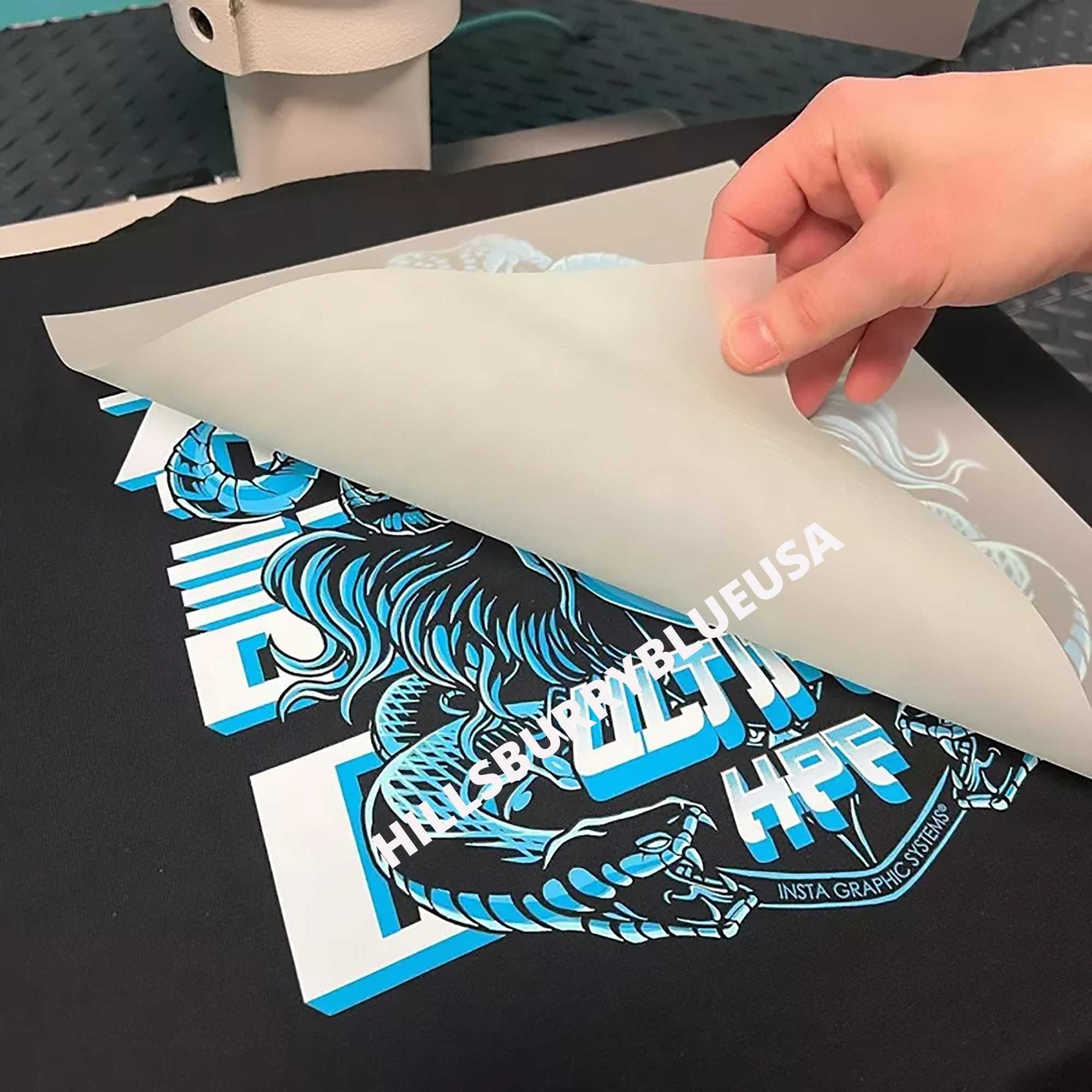

Direct-to-Film (DTF) printing has transformed the landscape of fabric printing by offering an innovative way to transfer designs onto fabrics with remarkable clarity and vibrancy. This method involves printing directly onto a special film that retains the design’s details and colors, which are then transferred onto the desired fabric using heat and pressure. Unlike traditional screen printing, DTF allows for more intricate designs without compromising the texture and feel of the fabric. It caters to a wide range of materials, making it a versatile choice for businesses and crafters alike.

The benefits of DTF transfers also extend to scalability and efficiency. As the popularity of custom apparel rises, businesses can implement DTF technology to meet diverse customer needs with ease. With minimal setup time compared to conventional methods, DTF allows for personalized prints that can be produced quickly, thus enhancing customer satisfaction. This flexibility in production has made DTF transfers an appealing option for small and large businesses looking to thrive in the competitive printing market.

The Impact of Custom DTF Printing Services

In recent years, custom DTF printing services have gained immense traction among entrepreneurs and crafters. Services like those offered by DTFPrinter have revolutionized how individuals create personalized designs, providing an intuitive user experience that simplifies the printing process. Customers can upload their artwork and receive high-quality custom transfers tailored to their specifications, eliminating the hurdles typically associated with traditional printing methods.

This approach has empowered many to infuse their creativity into apparel and merchandise, effectively bridging the gap between professional-grade prints and DIY projects. The ease of creating custom apparel has also contributed to the rise of small businesses and entrepreneurial ventures, wherein creators can monetize their designs without the need for significant upfront investments. Hence, custom DTF services not only enhance individual creativity but also stimulate economic growth within the creative industry.

Sustainability in DTF Printing: A New Era

As the world gravitates towards more sustainable practices, DTF printing technology is at the forefront of eco-friendly solutions in the apparel industry. By minimizing waste in the production process, DTF technology significantly reduces the environmental impact associated with traditional fabric printing methods. For instance, DTF transfers allow for precise printing that utilizes only the necessary materials, leading to less excess fabric waste.

Moreover, initiatives led by companies focused on sustainable DTF solutions are increasingly capturing consumer attention. With the integration of environmentally friendly inks and recyclable materials, DTF printing presents a compelling case for those looking to maintain a commitment to sustainability while still achieving high-quality results. By choosing DTF transfers, businesses not only elevate their product offerings but also respond to the growing market demand for eco-conscious practices.

Exploring Recent Developments in DTF Technology

The advancements in DTF technology are rapidly evolving, reflecting the increasing demand for high-quality printing solutions. Recent announcements, such as Eazydtf’s investment in new large-format printers, highlight the industry’s commitment to scaling up production capabilities to meet consumer expectations. Such investments not only enhance print quality but also boost operational efficiency, enabling businesses to offer quick turnarounds and meet tight deadlines.

Additionally, innovations in printing materials, such as enhanced films and eco-friendly inks, are making DTF transfers even more accessible to a broader audience. This ongoing development signifies that DTF technology continues to advance, ensuring that businesses can keep up with trends while providing superior product offerings. Understanding these developments is crucial for anyone looking to enter the bustling market of custom apparel.

Adapting to Market Needs with DTF Transfer Services

As the demand for custom apparel continues to surge, businesses are adapting by implementing specialized DTF transfer services. Snuggle’s introduction of a new trade service for DTF transfers illustrates a response to this market trend, allowing for large-scale production while maintaining exceptional quality. With capabilities to produce substantial quantities of prints daily, companies can better cater to the needs of both small businesses and larger retailers.

Such tailored services not only enhance operational efficiency but also empower businesses to diversify their offerings. By providing DTF transfer services, companies can attract a variety of clients, from individual crafters seeking small batches to businesses needing larger orders. This adaptability illustrates the versatility of DTF technology and its critical role in supporting a diverse range of printing applications.

Getting Started with DTF Transfers: Tips for Success

Embarking on your journey with DTF transfers can be an exciting yet daunting task. To ensure success, it is crucial to invest in quality equipment, including a reliable DTF printer and high-grade transfer film. Before diving into printing, take the time to learn the intricacies of the DTF process—understanding essential elements such as ink types, temperature settings, and curing methods will significantly influence the outcome of your prints.

Another vital aspect is experimentation with designs and techniques. Since DTF printing offers incredible detail and vibrancy, creatively pushing the boundaries of your designs can set you apart in a competitive market. By offering custom DTF services, you engage directly with customers, elevating their experience by providing unique and personalized products they cannot find elsewhere.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing high-quality designs onto a special film that is then applied to fabric through heat and pressure. This innovative technology allows for vibrant colors and intricate details while ensuring the fabric remains soft and comfortable. DTF transfers can be used on a variety of materials, including cotton and polyester.

What benefits does custom DTF printing offer for crafters?

Custom DTF printing provides crafters the ability to create personalized designs without the limitations of traditional printing methods. Services like those offered by DTFPrinter empower users to easily produce unique prints tailored to their specific needs, enhancing their crafting projects and allowing for greater creativity.

How does DTF technology contribute to sustainable printing solutions?

DTF technology offers sustainable printing solutions by significantly reducing fabric waste in the production process. By allowing precise printing directly onto materials, DTF helps minimize excesses and supports eco-friendly practices in the apparel industry. This aligns with modern initiatives focusing on environmental responsibility.

What recent developments are shaping the DTF transfer services market?

Recent developments in DTF transfer services, like Snuggle’s new trade service capable of producing up to 15,000 direct-to-garment prints daily, illustrate the growing demand for DTF printing. Companies are investing in state-of-the-art equipment and increasing their production capabilities to meet the needs of businesses and individual creators.

Why are DTF transfers considered a game-changer in the printing industry?

DTF transfers are considered a game-changer due to their ability to produce high-quality, detailed prints on various fabrics while being cost-effective and versatile. This technology bridges the gap between traditional and digital printing methods, offering an innovative approach that benefits entrepreneurs, creatives, and businesses alike.

How can someone start using DTF transfer technology in their business?

To start using DTF transfer technology in your business, invest in a quality DTF printer and transfer film, familiarize yourself with the printing and application process, and experiment with unique designs. Offering custom DTF printing services can also enhance your market appeal and attract new customers.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers have revolutionized the printing industry by allowing for vibrant and detailed designs on various fabrics. |

| Technology Overview | Direct-to-Film (DTF) transfers are created by printing on a special film which is then heat-pressed onto fabric. |

| Custom Printing Services by DTFPrinter | DTFPrinter launched a custom service to help creators easily obtain personalized prints with high quality. |

| Snuggle’s New Trade Service | Snuggle offers a new trade service capable of producing 15,000 direct-to-garment prints daily to meet increasing demand. |

| Sustainability Initiatives | DTF technology reduces waste in apparel production and aligns with eco-friendly practices. |

| Eazydtf’s Expansion | Eazydtf announced an investment to expand its capacity with new printers, highlighting the demand for DTF services. |

| Getting Started | Invest in quality equipment, familiarize with the process, and experiment with designs. |

Summary

DTF Transfers have emerged as a groundbreaking innovation in the printing industry, continually shifting how images are applied to fabrics. This method not only enhances print quality but also supports eco-friendly practices, making it a favored choice for businesses and creators alike. As we’ve seen through recent developments, such as the custom services by DTFPrinter and sustainability efforts by various companies, DTF technology is revolutionizing personalization and creativity in textile printing. For both newcomers and established players in the market, adopting DTF Transfers can provide significant opportunities for innovation and growth.