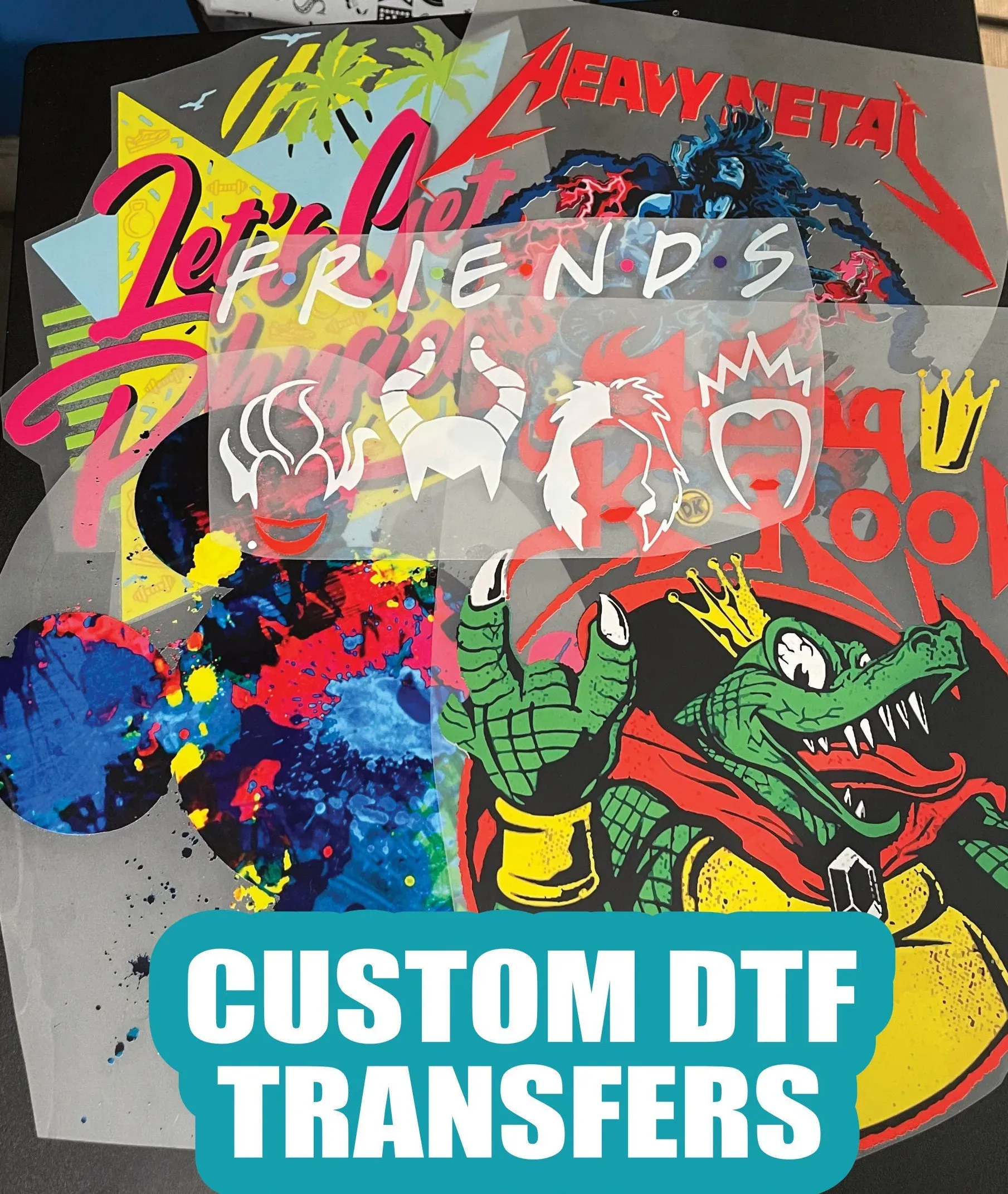

In the dynamic realm of textile printing, DTF transfers have quickly risen to prominence for their ability to combine vibrant visuals with excellent durability. Known as Direct-to-Film printing, this innovative technique allows for intricate designs to be applied to a wide array of fabrics, making it a preferred choice for both custom apparel enthusiasts and commercial applications. DTF transfer durability is particularly impressive, as these prints maintain their vividness through numerous washes without fading or cracking. As interest grows in sustainable printing practices, many manufacturers are also adopting eco-friendly inks, further enhancing the appeal of DTF technology. Join us as we delve deeper into the quality aspects of DTF transfers, solidifying their reputation as a cutting-edge solution in the textile printing industry.

Also referred to as Direct-to-Film (DTF) printing, this modern textile printing technology offers a novel way to transfer high-definition designs onto various fabrics. Utilizing advanced film and ink formulations, DTF printing delivers exceptional print quality and longevity, making it increasingly popular among fashion brands and DIY creators. This method distinguishes itself from traditional textile printing techniques by eliminating the need for pre-treatment, ensuring vivid prints that adapt seamlessly to different fabric types. Emphasizing the durability of these prints, they are engineered to withstand extensive wear and washing while retaining their color and detail. As industries shift towards more sustainable printing practices, DTF technology aligns with these trends by embracing eco-friendly materials and methods, ensuring the future of textile printing is bright and responsible.

Understanding the Advantages of DTF Transfers

DTF transfers offer several unique advantages that set them apart in the textile printing industry. One of the most significant benefits is their ability to produce vibrant colors and high-quality detail on various fabric types, including cotton, polyester, and blends. This versatility makes DTF printing an attractive option for businesses looking to diversify their product range without compromising on quality.

Additionally, DTF transfers do not require pre-treatment of fabrics like traditional Direct to Garment (DTG) printing, simplifying the workflow. This efficiency allows businesses to cater to rapid production demands without sacrificing print quality, making DTF a preferred choice for both small custom shops and larger apparel manufacturers.

The Quality Factors of DTF Printing

The quality of DTF printing is largely attributed to the advanced ink formulations used in the process. With the advent of water-based and eco-solvent inks, the vividness of colors has significantly improved, ensuring that prints maintain their allure even after multiple washes. This innovation not only enhances the consumer experience but also supports brands aiming for sustainable printing practices.

Moreover, the choice of transfer film plays a crucial role in the overall print quality. High-resolution films designed specifically for DTF applications ensure that intricate designs are transferred cleanly and precisely, without loss of detail. By investing in quality materials, businesses can guarantee that their customer’s expectations are met regarding both aesthetic appeal and durability.

Enhancing DTF Transfer Durability

Durability is a vital aspect of DTF transfers that should not be overlooked. One of the primary advantages of this printing method is its remarkable wash resistance. DTF prints can endure over 50 washes while retaining their vibrant colors, making them ideal for activewear and frequently laundered garments. This level of durability is a game-changer for brands that prioritize long-lasting products.

Furthermore, the robust adhesive used in DTF transfers enhances the longevity of the prints. Designed to bond tightly with fabric fibers, this adhesive prevents stretching, fading, and cracking, ensuring that the designs remain intact and visually appealing over time. As consumers increasingly seek durable apparel, DTF printing offers an unmatched solution in the market.

Innovations Fueling DTF Printing Technology

The continuous evolution of DTF printing technology is marked by several innovative advancements. One of the most notable developments has been in the production of enhanced films and adhesives that improve the flexibility and overall durability of the prints. These innovations ensure that designs retain their integrity even under strenuous conditions.

In addition to mechanical enhancements, the focus on eco-friendly inks is reshaping the landscape of DTF printing. By using biodegradable formulations, manufacturers not only reduce their environmental impact but also meet the growing consumer demand for sustainable practices. This transition reflects a broader trend in the printing industry toward responsible production methods that benefit both the planet and the customer.

The Cost-Effectiveness of DTF Transfers

Considered one of the more cost-effective options in textile printing, DTF transfers eliminate the need for costly pre-treatment processes while still delivering high-quality results. This efficiency translates to lower operational costs for businesses, allowing them to offer competitive pricing to customers without sacrificing quality.

Moreover, the ability to print on a variety of fabrics without the need for specialized equipment further enhances the cost-effectiveness of DTF printing. As businesses can serve a wider range of applications with a single printing method, this reduces the need for multiple machines, saving both time and resources.

Sustainable Practices in DTF Printing

Sustainability is an increasingly important factor in choosing printing practices, and DTF technology is rising to meet this challenge. The utilization of eco-friendly inks in DTF printing not only minimizes environmental impact but also caters to a growing consumer base that prioritizes sustainability in their purchasing decisions.

In addition to using less harmful inks, the efficiency of the DTF process itself contributes to sustainable practices. With fewer resources required to produce high-quality prints, businesses can reduce waste and promote a more environmentally responsible approach to textile printing. This commitment to sustainability not only appeals to customers but can also enhance brand reputation.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that is then transferred onto fabric using heat and pressure. This method enables high-quality and vibrant prints on various garment types without pre-treatment, offering exceptional flexibility in textile printing.

How does DTF printing quality compare to traditional methods?

DTF printing quality surpasses traditional methods due to advanced ink formulations and high-resolution films. This technology achieves greater detail, color accuracy, and vibrancy, making it ideal for intricate designs and providing a superior finish on diverse fabric types.

What is the durability of DTF transfers when used on garments?

DTF transfers are highly durable, designed to withstand over 50 washes without losing vibrancy. Thanks to robust adhesive strength, DTF prints resist stretching and fading, ensuring garments maintain their fresh appearance even with regular use.

Are there any eco-friendly options available in DTF printing technology?

Yes, the DTF printing industry is evolving towards sustainable practices, with many manufacturers developing eco-friendly inks. These inks offer vivid colors while being less harmful to the environment, catering to brands focused on sustainability.

Can DTF transfers be applied to all types of fabrics?

Absolutely! DTF transfers can be used on a wide range of fabrics, including both light and dark textiles. This versatility makes DTF printing technology suitable for various garment styles and materials, maximizing design potential for brands.

What factors contribute to the print quality of DTF transfers?

Several factors influence DTF transfer quality, including advanced ink formulations, the type of transfer film, and ensuring high-resolution images. Using top-grade films and optimizing image resolution are crucial for achieving the best results in DTF printing.

| Feature | Description |

|---|---|

| DTF Printing Technology | A modern method that prints vibrantly on various fabrics, combining high detail and color richness. |

| Ink Quality | Utilizes advanced formulations (water-based and eco-solvent) ensuring stunning imagery and reduced environmental impact. |

| Transfer Film | High-resolution films are essential for achieving clarity and detail in designs transferred onto fabric. |

| Image Resolution | Starting with high-resolution images prevents pixelation, ensuring sharp end results. |

| Wash Resistance | DTF prints are durable and maintain vibrancy through over 50 washes, ideal for frequently laundered garments. |

| Adhesive Strength | Specialized adhesives bond strongly with fabric, enhancing resistance to wear and fading. |

| Innovations | Focus on enhanced films and eco-friendly inks are driving improvements in print durability and sustainability. |

Summary

DTF transfers represent a revolutionary advancement in the textile printing industry, revolutionizing how designs are applied to fabrics. With the ability to produce vibrant, high-quality prints that withstand the test of time, DTF transfers offer unparalleled durability that is especially appreciated in the fashion and apparel market. These transfers can endure numerous washes without fading, making them perfect for clothing that sees regular use. Furthermore, ongoing innovations in film quality and eco-friendly inks underscore the commitment to improving the sustainability and performance of DTF printing technology, a paramount consideration for modern consumers and businesses alike.