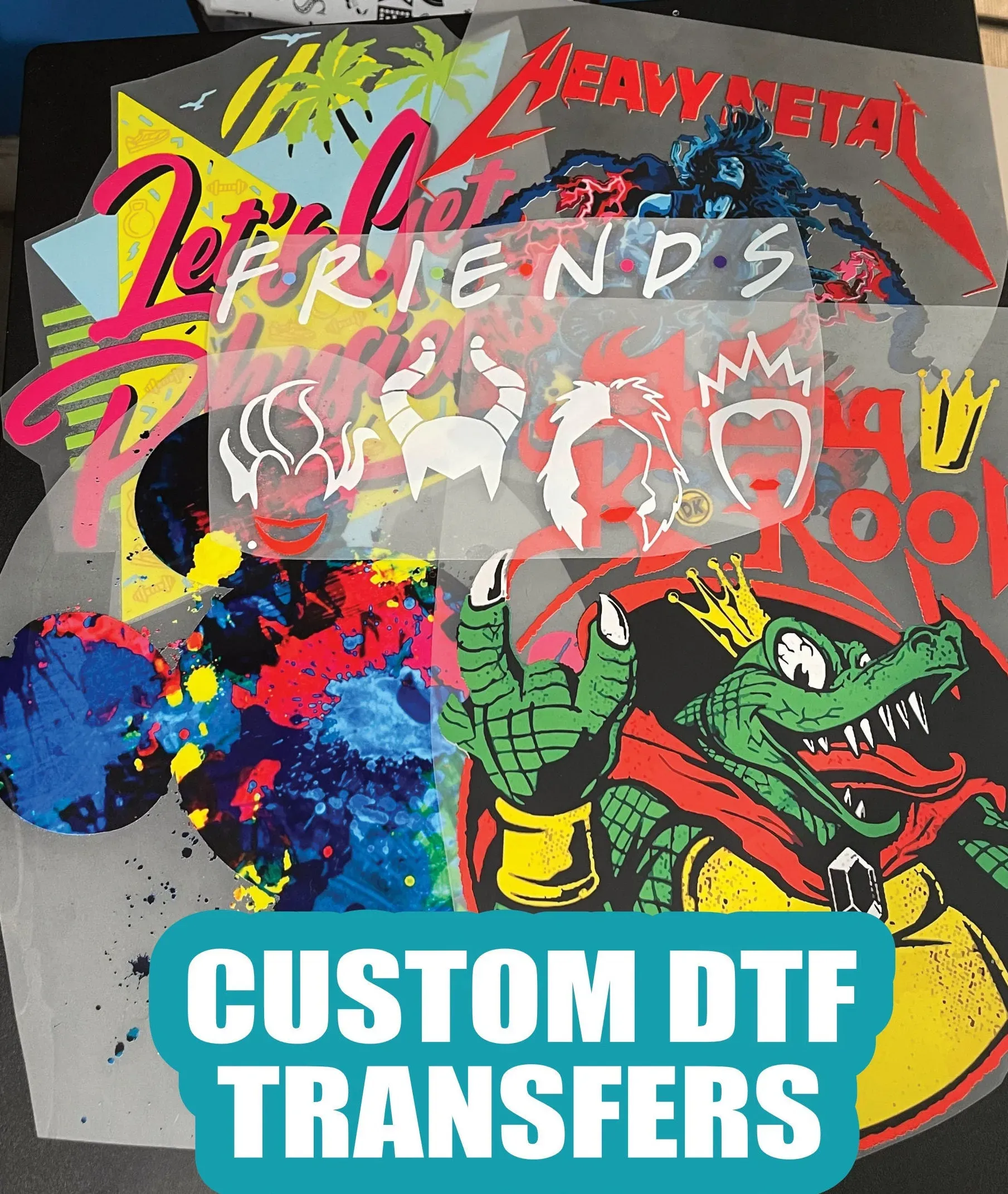

DTF Transfers, or Direct-to-Film Transfers, represent an innovative approach in the world of custom apparel printing, offering a versatile and efficient method for transferring designs onto fabrics. Unlike traditional screen printing, DTF printing uses a special transfer film to produce vibrant and detailed images, allowing for a wider range of materials, including cotton and polyester. This modern textile printing technique not only caters to intricate designs but also minimizes waste, aligning with sustainability goals in the printing industry. With a low minimum order requirement, DTF Transfers provide an excellent solution for small businesses and individual projects alike. As the demand for eco-friendly and customized apparel continues to rise, DTF printing is establishing itself as a compelling alternative to conventional methods like screen printing.

Direct-to-Film transfers, often referred to by their acronym DTF, are revolutionizing the way designs are applied to textiles. This innovative technique has been recognized within the realm of custom garment decoration, primarily because of its ability to yield vibrant prints with intricate details, especially when compared to traditional methods such as screen printing. DTF printing offers significant flexibility, catering to various fabric types while promoting a more sustainable approach to textile printing by minimizing water usage and waste. With the growing emphasis on sustainable printing practices, this method provides an appealing solution for businesses looking to enhance their eco-friendly credentials. As the market for personalized apparel grows, the integration of techniques like DTF is paving the way for more creative and responsible printing solutions.

What Sets DTF Transfers Apart from Traditional Methods?

Direct-to-Film (DTF) transfers stand out due to their unique printing methodology that combines modern technology with creative flexibility. Unlike traditional methods like screen printing, which utilize stencils and complex setups, DTF printing involves applying designs onto a polymer film that later adheres to fabric using heat. This innovative approach allows for vibrant color reproduction and intricate designs, making it ideal for custom apparel and promotional items. Additionally, DTF’s versatility extends across various fabric types, including cotton, polyester, and blends, further enhancing its appeal in the textile printing market.

The simplification of the printing process with DTF transfers contributes to a faster turnaround time, especially advantageous for small businesses or individual projects. The ability to create detailed images without the need for multiple screens allows for one-off prints or low minimum orders, addressing the growing demand for personalized clothing. Furthermore, as sustainability becomes increasingly relevant in the industry, many DTF inks are now water-based and eco-friendly, making this method not only an efficient choice but also a conscious one for environmentally-aware consumers.

Exploring the Benefits of Screen Printing for Bulk Orders

Screen printing, a time-honored textile printing technique, remains a staple in the industry, particularly for bulk production runs. The process starts with creating a stencil, which allows ink to be pushed through onto the fabric, making it well-suited for large orders. The cost-effectiveness of screen printing becomes evident with increased quantity; as the volume of prints rises, the cost per piece decreases significantly, making it a go-to for businesses looking to produce large quantities of apparel without breaking the bank.

Moreover, screen printing provides excellent ink opacity, especially on dark fabrics, allowing vibrant colors to pop and maintain their intensity even after multiple washes. This durability ensures that products retain their quality over time, making them ideal for brands that emphasize longevity and visual appeal. For companies that prefer traditional methods and established production practices, screen printing offers a wealth of resources and expertise, further solidifying its role as a reliable option in textile printing.

As businesses seek reliable and aesthetically pleasing products, the longevity and consistency of screen-printed items continue to resonate in the market.

Balancing Sustainability in DTF Transfers and Screen Printing

In an era where sustainability is paramount, both DTF transfers and screen printing are evolving to embrace more environmentally friendly practices. DTF printing has risen to the occasion by adopting advancements that reduce water usage and incorporate eco-friendly inks. This not only addresses the pressing concerns of waste but also underlines the industry’s shift towards minimizing its ecological footprint. As consumers become increasingly conscientious about their purchasing decisions, DTF provides a compelling option for brands looking to align with sustainable values.

On the other hand, the screen printing sector has also made significant strides in sustainability through innovative practices such as using biodegradable inks and reducing harmful chemical consumption. Some shops offer eco-conscious options, combining traditional methods with modern sustainability efforts. As this trend grows, both DTF and screen printing can coexist as viable solutions that cater to demands for vibrant designs while promoting environmental responsibility in the textile printing arena.

Making the Right Choice: DTF vs. Screen Printing

The choice between DTF transfers and screen printing ultimately hinges on the specific needs of the project at hand. Those focused on bulk production would benefit from the cost-effective nature of screen printing, as the economies of scale play a significant role in reducing overhead costs. However, for smaller orders or designs requiring a high level of detail and versatility, DTF printing proves to be the ideal solution. Its ability to handle a wider range of fabric types without sacrificing quality makes it a versatile contender in the custom apparel market.

To make an informed decision, it’s essential to consider several factors including design complexity, production volume, and budget constraints. Each method has its unique advantages, and understanding these can better align your printing choices with your business objectives. As the demand for personalized products grows, choosing the right printing technique can set a brand apart in today’s competitive landscape.

Design Complexity: A Key Factor in Printing Choices

When choosing between DTF transfers and screen printing, design complexity plays a pivotal role in the decision-making process. DTF printing excels in producing intricate designs with vibrant colors, which is particularly beneficial for detailed artwork, photographs, and intricate graphics. Its capability of handling various colors in one print job significantly enhances its appeal for custom apparel printing, making it the preferred choice for artists and designers looking to showcase their creativity without limitation.

Conversely, screen printing thrives in simplicity, catering best to bold graphics and less intricate designs. While the method can achieve stunning results on larger orders, it may fall short in the representation of finer details compared to DTF. This dichotomy highlights the importance of assessing design requirements closely to ensure that the selected printing method not only meets expectations but also brings the artistic vision to life effectively.

Frequently Asked Questions

What are DTF Transfers and how do they compare to screen printing?

DTF Transfers, or Direct-to-Film Transfers, involve printing designs onto a transfer film that is applied to fabric using heat. They provide vibrant colors and detailed prints, making them ideal for custom apparel printing, while screen printing uses a stencil to push ink through to fabric. DTF is excellent for small orders, whereas screen printing is cost-effective for bulk production.

Can DTF Transfers be used on all types of fabric?

Yes, DTF Transfers are versatile and can be applied to a wide variety of fabrics including cotton, polyester, and blends. This flexibility makes DTF printing a superior choice for textile printing, allowing for custom designs on various apparel materials.

Are DTF Transfers eco-friendly compared to traditional printing methods?

DTF Transfers are considered more sustainable than traditional screen printing due to reduced water usage and the development of eco-friendly inks. Many DTF printing processes have improved to minimize environmental impact, addressing the growing demand for sustainable printing solutions.

What are the benefits of using DTF Transfers for custom apparel printing?

The benefits of DTF Transfers for custom apparel printing include vibrant color output, the ability to print detailed designs, lower minimum order quantities, and simplified production processes. These factors make DTF a popular option for small businesses looking for quality and flexibility in their textile printing.

How do DTF Transfers handle intricate designs compared to screen printing?

DTF Transfers excel in producing intricate designs due to their ability to achieve high-resolution prints and vibrant colors. While screen printing can handle less complex designs efficiently, DTF printing is better suited for detailed graphics, making it ideal for custom projects that require precision.

Which printing method is more cost-effective for bulk orders, DTF Transfers or screen printing?

Screen printing typically becomes more cost-effective for bulk orders as the cost per unit decreases with higher quantities. In contrast, DTF Transfers are advantageous for small quantities or custom designs, as they have lower upfront costs and no minimum order requirements, catering to diverse printing needs.

| Feature | DTF Transfers | Screen Printing |

|---|---|---|

| Definition | Prints on transfer film using heat and pressure. | Creates a stencil through which ink is applied to fabric. |

| Advantages | Vibrant, high-resolution prints; low minimum orders; simplified workflow; eco-friendly. | Durable prints; cost-effective for bulk; excellent ink opacity; traditional method. |

| Best For | Small orders, custom designs, and a variety of fabrics. | Bulk production and products needing high durability. |

| Environmental Impact | Less water usage; many inks are eco-friendly. | Introduces biodegradable inks; generally higher water consumption. |

Summary

DTF Transfers offer a modern solution for printing designs with vibrant colors and flexibility, making them an excellent choice for small businesses and custom orders. As printing technology evolves, so do the methods available, making it essential for businesses to consider their specific needs. DTF Transfers provide advantages in intricate designs and ease of use compared to traditional screen printing, which excels in bulk production and durability. By understanding the differences and benefits of each method, you can choose the right one to meet your printing goals.