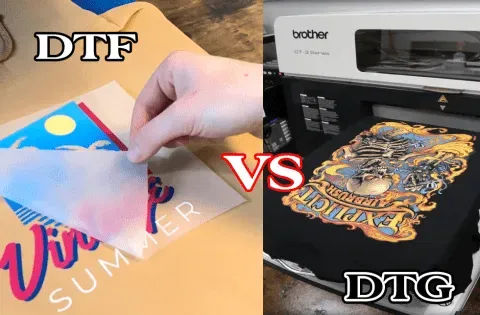

In the competitive realm of custom apparel, the choice between DTF vs. DTG printing can significantly influence your business outcomes. Both Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing offer unique advantages, making them increasingly popular choices for entrepreneurs. To make an informed decision, it is essential to understand these printing technologies and how they contribute to fabric printing methods. DTF printing shines in its versatility across various textiles, while DTG printing is renowned for its high-quality, intricate designs. This article will guide you through the fundamentals of DTF vs. DTG, shedding light on which method aligns best with your specific business needs.

When it comes to selecting the right approach for customizing apparel, the debate often revolves around two key printing techniques: Direct-to-Film (DTF) and Direct-to-Garment (DTG). These advanced printing solutions cater to the growing demands of personalized clothing items. Understanding the nuances between these innovative printing technologies is crucial for businesses aiming to meet diverse consumer preferences effectively. While DTF excels in adaptability to various materials, DTG offers unmatched quality for detailed designs. As we explore these fabric printing methods, it will become clear how they can impact your product offerings and customer satisfaction.

The Rise of Custom Apparel: Why Choose DTF or DTG?

The custom apparel industry has witnessed exponential growth in recent years, driven by consumer demand for personalized and unique clothing options. With this surge in popularity, businesses must adapt by selecting the most suitable printing technology that aligns with their creative visions and operational needs. DTF and DTG printing methods have emerged as frontrunners in this domain, each offering distinct benefits tailored to different market segments. Businesses that leverage these technologies can stand out in a crowded marketplace by providing high-quality, custom products that resonate with their target audience.

Choosing between DTF and DTG doesn’t just influence production quality; it also affects branding, customer satisfaction, and profitability. As more consumers seek personalized garments, understanding the intricacies of DTF and DTG can empower businesses to make strategic decisions. By investing in the right printing method, entrepreneurs can enhance the quality of their offerings and meet rising consumer expectations in personalized apparel.

Exploring the Processes of DTF and DTG Printing

The methods of DTF and DTG printing reflect the ongoing evolution of printing technology, catering to the diverse needs of modern businesses. DTG printing utilizes a direct inkjet technique similar to conventional printers, applying ink seamlessly onto fabric, which facilitates vibrant designs and detailed imagery. This method is ideal for intricate artwork and offers remarkable color depth, providing a high-quality finish that stands out in the competitive custom apparel landscape.

On the other hand, DTF printing challenges conventional methods through its effective transfer process. By printing designs onto a specialized film that is then heat transferred onto the fabric, DTF offers flexibility that DTG may lack when it comes to fabric compatibility. This adaptability allows businesses to cater to a diverse range of materials, from cotton to polyester blends, thereby broadening their product offerings and enhancing overall consumer appeal.

Understanding the Advantages and Disadvantages of DTF vs. DTG

Both DTF and DTG printing methods come with unique advantages and potential drawbacks that businesses should consider before making a decision. DTF printing stands out for its versatility and faster production speeds, making it a preferred choice for large orders often required by enterprises seeking to minimize turnaround times. The ability to print on various fabrics also means businesses can expand their custom apparel lines without being restricted to specific materials.

Conversely, while DTG printing excels in delivering stunning quality and intricate designs with vivid colors, it does tend to operate slower, especially in comparison to DTF. This can make DTG less ideal for larger batch production. Understanding these trade-offs is crucial for entrepreneurs focusing on optimizing their operational efficiency while maintaining high standards in quality and aesthetic appeal.

Cost Efficiency: Analyzing DTF and DTG for Your Business

Cost analysis is an integral aspect when determining the suitable printing method for your business. DTG printing is often more cost-effective for small batch runs given its lower initial setup costs and minimal investment in materials. This is particularly beneficial for businesses dealing with custom orders that prioritize fine details and artistic designs.

In contrast, DTF printing shines in larger production runs, as the speed and efficiency of the process allow for reduced costs per unit. Furthermore, DTF’s adaptability to various fabric types ensures that businesses can produce a wider range of products without incurring heavy losses, maximizing overall profitability in the custom apparel market.

Fabric Compatibility: How DTF and DTG Meet Diverse Needs

Understanding fabric compatibility is critical for businesses that aim to cater to a diverse clientele. DTG printing works best on natural fibers like cotton, making it an excellent choice for apparel that emphasizes comfort and breathability. This method allows printers to create soft, luxurious garments that customers love to wear, especially when intricate designs are a priority.

DTF printing, however, offers unmatched versatility, as it can be applied to a wider range of fabric types, including polyester and synthetic blends. This makes DTF a superior choice for businesses that wish to appeal to a broader demographic or produce promotional items across various materials. The ability to cater to multiple fabric types can be a game-changer for companies looking to expand their custom merchandise offerings.

Future Trends in Printing Technologies for Custom Apparel

As the landscape of printing technology continues to evolve, businesses must stay ahead of trends to maintain a competitive edge in the custom apparel market. Recent advancements in both DTF and DTG printing have led to better quality, faster production capabilities, and enhanced durability of prints. Innovations focusing on environmental sustainability, such as eco-friendly inks and fabrics, are gaining traction within these technologies, influencing consumer purchasing decisions.

Companies that embrace these evolving trends and integrate them into their operations can position themselves as leaders in the custom apparel market. By investing in state-of-the-art printing technology and sustainable practices, businesses can not only improve their production efficiency but also meet the ethical expectations of today’s environmentally conscious consumers.

Frequently Asked Questions

What are the main differences between DTF vs. DTG printing methods?

DTF (Direct-to-Film) and DTG (Direct-to-Garment) are both popular fabric printing methods, but they differ significantly. DTG printing applies ink directly onto the garment, providing high-quality, vibrant colors especially suited for cotton fabrics. In contrast, DTF printing uses a film transfer method, allowing compatibility with a wider range of fabrics, including polyester. Additionally, DTF printing offers faster production speeds compared to the typically slower DTG process.

Which method is better for custom apparel: DTF vs. DTG?

The choice between DTF and DTG for custom apparel depends on your specific needs. If you require high-quality, intricate designs primarily on cotton fabrics, DTG printing is ideal. However, if you need a versatile printing solution that works on various fabric types and need quicker turnaround times, especially for larger orders, DTF printing would be the better choice.

Can I use DTF printing on any fabric type compared to DTG printing?

Yes, DTF printing is significantly more versatile than DTG printing, as it can be applied to a variety of fabric types, including cotton, polyester, and blends. DTG printing, on the other hand, generally works best on natural fibers, particularly cotton, limiting its range for custom apparel applications.

What are the cost considerations when choosing between DTF vs. DTG printing?

Cost considerations for DTF vs. DTG printing depend on your order size. DTG printing can offer cost benefits for smaller batches due to lower initial investment, while DTF printing can lead to savings for larger production runs due to its faster processing and ability to handle diverse fabrics efficiently.

How does the print quality of DTF compare to DTG printing?

DTG printing is renowned for producing high-quality prints with vibrant colors and intricate details, making it suitable for graphic-heavy designs. DTF printing has improved significantly and offers good print quality, but it may not match the softness and detail that DTG provides, especially on cotton fabrics. The choice ultimately depends on the design’s requirements.

What are the advantages and disadvantages of DTF vs. DTG printing?

DTF printing advantages include versatility across different fabric types and faster production speeds. However, prints can feel heavier and have potential color matching variations. DTG printing offers high-quality, soft prints ideal for detailed designs but has slower production rates and is restricted to certain fabrics, primarily cotton.

| Aspect | DTG Printing | DTF Printing |

|---|---|---|

| Definition | Uses inkjet technology to print designs directly onto fabric. | Prints designs onto a special film which is then heat transferred to the fabric. |

| Advantages | High-quality, vibrant prints and soft feel; great for intricate designs. | Versatile with fabric types; faster production speed; exceptional adhesion. |

| Disadvantages | Slower production speeds; limited to best performance on cotton. | Heavier final prints; potential for color matching variations. |

| Best for | Small batches with intricate designs. | Larger orders and diverse fabric applications. |

| Cost Efficiency | Lower initial investment for small runs. | More cost-effective for larger runs due to efficiency. |

| Fabric Compatibility | Best on natural fibers like cotton. | Works well with cotton, polyester, and blends. |

Summary

DTF vs. DTG represents a crucial decision point for businesses in the custom apparel industry aiming to optimize their production capabilities. Understanding the fundamental differences between these two methods—DTG’s ability to deliver high-quality, intricate prints ideal for small runs and its preferences for natural fabrics versus DTF’s versatility and speed suitable for larger orders—enables businesses to align their printing method with their specific needs. As the custom apparel market continues to evolve, embracing the right printing technology can significantly impact operational efficiency and overall customer satisfaction.