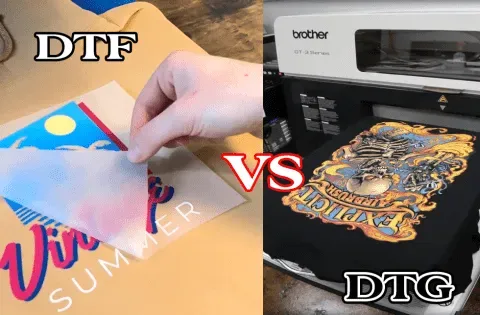

DTF vs DTG has become a central question for brands seeking the right balance of color, feel, and production practicality. Understanding DTF printing advantages helps brands evaluate flexibility across fabrics and print consistency. When weighing DTG vs DTF, many teams consider the overall hand feel, color depth, and how each method handles dark garments. For many designers, choosing the best apparel printing method means weighing setup costs, run quantities, and per-item value. A practical look at the DTF transfer process and the cost of DTF vs DTG shows DTF can offer strong results with broader material compatibility.

Seen through a broader lens, the debate can be described as film-based transfer versus direct-on-fabric printing, with each path offering unique workflow benefits. Other terms you’ll hear include film-to-garment transfer, pigment-based versus water-based inks, and the role of pretreatment in achieving color fidelity. LSI-friendly concepts such as fabric compatibility, print durability, and hand feel help content creators map products to the right technique without getting lost in jargon. Ultimately, brands choose a strategy that aligns with material mix, design complexity, and production speed, drawing on the strengths of both transfer-on-film and direct-to-textile methods.

DTF printing advantages: versatile performance across fabrics

DTF printing advantages extend beyond fabric compatibility. It offers strong color depth, reliable performance on poly blends and cotton, and broad vibrancy for bold graphics across a wide base of fabrics.

In practice, DTF’s transfer process enables you to push vibrant designs on a diverse catalog. This versatility makes it a compelling option for brands evaluating the best apparel printing method and seeking consistent results across mixed materials.

DTF vs DTG: A side-by-side look at finish, cost, and fabric suitability

DTF vs DTG showcases a set of trade-offs: DTG often delivers a softer hand and subtle gradients on 100% cotton, while DTF shines on dark colors and non-cotton fabrics with strong color saturation.

Understanding the differences helps brands decide which path to take for each product line. When evaluating the best apparel printing method, many teams choose DTF for flexibility and DTG for premium cotton pieces, recognizing the cost implications of each route.

Best apparel printing method: aligning product goals with technique

Choosing the best apparel printing method means mapping fabric, design complexity, and customer expectations to the strengths of each process. This alignment ensures consistent quality and a scalable workflow that matches your catalog.

The decision framework should consider fabric mix, color requirements, and expected order velocity to determine whether DTF transfer process flexibility or DTG’s soft hand is the better fit for your brand.

Cost of DTF vs DTG: budgeting for small runs and long-term growth

Cost considerations are central to strategy. The cost of DTF vs DTG varies with run size, fabric, and pretreatment needs, with DTF often offering lower per-unit costs for short to mid-length runs on non-cotton fabrics.

DTG may require a higher upfront investment in printers and maintenance, but it can justify premium pricing on cotton garments due to the soft hand feel and gradient quality, making it attractive for flagship products.

DTF transfer process: steps from design to durable garment finish

The DTF transfer process typically starts with printing the design onto a PET film using pigment inks, followed by the application of a bonding powder, curing, and then heat pressing the transfer onto the garment.

Each stage—print, cure, and press—affects color fidelity, durability, and hand feel. Efficient workflow planning, file prep, and color optimization help minimize waste and maximize consistency across runs.

Decision framework: when to choose DTF or DTG for your brand

Define your product mix, fabrics, base colors, and desired outcomes to guide the initial choice between DTF and DTG.

Assess order size, turnaround needs, budget, and maintenance requirements. A deliberate plan that considers scalability, sustainability, and customer expectations will help you balance quality, speed, and cost over time.

Frequently Asked Questions

What are the key DTF printing advantages in the DTF vs DTG comparison?

DTF printing advantages include strong color saturation and reliable results across a wide range of fabrics, including poly blends and dark bases. In a DTF vs DTG comparison, DTF typically offers lower setup costs and per-unit costs for small to mid-length runs, plus easier handling of dense, multi-color designs. While DTG can shine on 100% cotton with a soft hand, DTF’s transfer process and film-based method provide versatility and consistent quality across diverse product lines.

How does the cost of DTF vs DTG impact planning for a small apparel line?

The cost of DTF vs DTG depends on run size, fabric, and maintenance needs. DTF generally delivers lower per-unit costs for short to mid-length runs and non-cotton fabrics, with simpler prep and fewer process variables. DTG incurs higher ink usage, pretreatment, and machine upkeep, which can raise unit costs on cotton-heavy designs. For many brands, starting with DTF offers budget-friendly flexibility, while DTG may justify its price on premium cotton items with soft hand and gradient appeal.

In a mixed catalog, which is the best apparel printing method: DTG vs DTF?

For a mixed catalog, the best apparel printing method often balances both techniques. DTG is ideal for flagship cotton tees with sharp gradients and a premium hand feel, while DTF excels on dark fabrics and a broader fabric mix, including polyester blends. A hybrid approach—DTF for non-cotton and dark items, DTG for cotton-focused pieces—can maximize quality, speed, and cost efficiency across your product line.

What is the DTF transfer process, and how does it compare to DTG in workflow?

The DTF transfer process involves printing the design onto a PET film with pigment inks, applying a bonding powder, curing the film, and heat-pressing the transfer onto the garment. This contrasts with DTG, which prints ink directly onto fabric using a textile printer. In workflow terms, DTF adds film handling and powder curing steps, offering versatile results on various fabrics, while DTG emphasizes direct-on-fabric printing with pretreatment and post-processing to optimize color on cotton.

Is DTG vs DTF better for color fidelity and gradients across fabrics?

DTG excels at color fidelity and smooth gradients on light, 100% cotton fabrics, delivering photo-like detail with a soft hand. DTF provides robust color on a wider fabric range, including dark or non-cotton items, though gradients may be less subtle than DTG on some cotton substrates. Choosing DTG vs DTF often depends on the base fabric and the desired texture: DTG for cotton-focused lines; DTF for versatile, durable results across mixed fabrics.

What factors should brands consider to optimize quality and cost when choosing between DTF vs DTG for their product line?

Brands should consider fabric mix, base colors, order size, and production velocity. Also weigh setup costs, maintenance, and per-unit expenses, plus the desired hand feel and wash durability. A practical framework includes evaluating fabric diversity, print complexity, and the potential for a hybrid approach (DTF for non-cotton/dark items and DTG for cotton-focused pieces). Aligning these factors with sustainability goals and scalability helps optimize quality and cost across the catalog.

| Topic | DTF Highlights | DTG Highlights |

|---|---|---|

| What DTF vs DTG Really Means | DTF stands for Direct-to-Film and involves printing designs on a PET film, then transferring to fabric; DTG stands for Direct-to-Garment and prints directly onto fabric. Both aim for high-quality, vivid images, but differ in workflow, materials, and fabrics they excel on. | DTG prints ink directly onto the garment (usually cotton) with a soft hand feel and excellent gradients on light fabrics; it often requires pretreatment for vibrant results on dark fabrics and depends on fiber absorption. |

| How It Works | DTF: print on PET film using pigment inks, apply bonding powder, cure, then heat-press transfer onto a garment. | DTG: direct-on-fabric printing with water-based inks; primary canvas is cotton; pretreatment may be needed for vibrant results on dark fabrics. |

| Key Differences | – Material compatibility: DTF works across a wide range of fabrics, including blends and darker bases. | – Print quality and color fidelity: DTG delivers smooth gradients and photo-like quality on light fabrics; DTF excels in strong color saturation across fabrics. |

| – Durability and hand feel: DTF prints are typically durable with a slightly textured finish; DTG yields a soft hand on cotton. | – Setup and costs: DTG often requires higher upfront investment in a printer, pretreatment, and maintenance; DTF can be more cost-efficient per unit for small runs and complex designs. | |

| Cost Considerations | – DTF: lower per-unit cost for short to mid-length runs and versatility across fabrics. | – DTG: higher upfront costs (printer, pretreatment) and ongoing maintenance, but premium feel on cotton can justify pricing. |

| Print Quality, Durability & Wash | – DTF: vibrant colors, strong color coverage, durable with a textured hand; good wash durability across fabrics. | – DTG: exceptional detail and smooth color transitions on light fabrics; long-term durability depends on pretreatment, curing, and wash instructions. |

| Fabric Compatibility & Color Management | – DTF works across polyester, blends, and cotton with consistent color management and white underbase adjustments as needed. | – DTG is best on 100% cotton or high-cotton blends; color management relies on calibration, ICC profiles, and pretreatment for consistency. |

| Environmental & Maintenance Considerations | – DTF uses powders and films; maintenance involves heat presses and routine cleaning; disposal considerations apply. | – DTG relies on pretreatments and inks; maintenance includes printer upkeep, head cleaning, and waste handling. |

| Practical Scenarios | – Frequent design changes, mixed fabrics, and dark garment colors favor DTF for flexibility and cost efficiency. | – Premium cotton tees, photo-like prints, and soft hand feel favor DTG; a hybrid approach can optimize overall quality and cost. |

| Decision Framework | – Define product mix: fabrics and base colors anticipated most often. | – Assess order size and velocity: how fast you need to turn orders. |

| – Evaluate budget and maintenance: justify DTG’s upfront costs, or leverage DTF for versatility and lower setup. | – Consider customer experience and scalability: plan for future lines and color complexity. |

Summary

DTF vs DTG is a strategic decision for apparel brands, shaped by fabric choices, design complexity, order size, and brand positioning. DTF printing offers versatility across fabrics, strong color reproduction, and cost efficiency for diverse runs, while DTG excels in soft hand feel, high-detail gradients, and premium cotton applications. Many brands benefit from a hybrid approach: use DTF for non-cotton or dark items and DTG for cotton-focused pieces. To choose the best path, define your product mix, estimate order velocity, assess budget and maintenance, consider the desired customer experience, and plan for scalability. By mapping goals to each method’s strengths, you can build a production plan that balances quality, speed, and cost while supporting sustainable growth.